Overview of PFR Speed Reducer

Overview of PFR Speed Reducer

● Square flange output design ensure fast connection with any motor

● High rigidity & torque due to the use of needle roller bearing

● Spiral bevel gears are adopted to ensure the lowest backlash

● Space-saving design

Motors can be mounted at a 90 degree to save the space

● No leakage of grease

High viscosity and non-separated grease is used to avoid the leakage.

● Square flange output design ensure fast connection with any motor

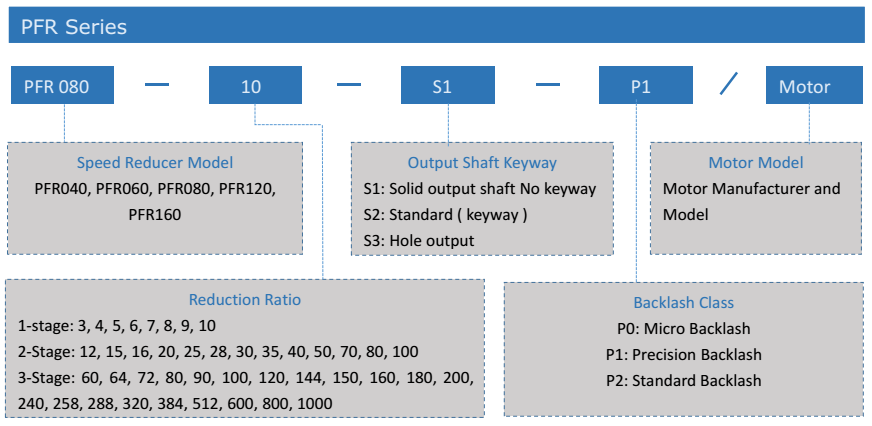

Indication of Model Numbers of PFR Speed Reducers

Description of PFR Planetary Speed Reducer

PFR series right angle gearbox is designed for solve the problems of space. The compact structure of PFR speed reducer provides customer with a good solution when installation space or clearance are limited. High precision and solid construction make PFR speed reducer more valuable than other similar gearbox. Two ends of needle roller bearings with high precision on the shaft backup the planetary gears to improve the torsional stiffness of speed reducer. Meanwhile, this planetary gearbox is also an economy pecision gear reducer, providing an excellent choice for customers who has limited budget. In addition, flanged output design make it easier to connect with the equipment.

Application of PFR Precision Planetary Gearbox

Precision planetary reducer is widely used in various fields: environmental protection equipment, precision instruments, flame cutting, CNC machine tools, tool machinery, automation industry, printing machinery, textile printing and dyeing, pharmaceutical leather, environmental protection equipment, coal equipment, cement equipment, beer drink, mining machinery, wire rope transmission life test machine, glass equipment, winding machine, food packaging, welding equipment, CNC machine tools, laser cutting, industrial robot measuring equipment, rubber plastics, petrochemical, lifting transportation and other light and heavy industry, mechanical transmission and precision control field.

Taiqi Seiko Superior Proizvodnja Processes of PFR Planetary Gearbox:

Sve komponente su kontrolisane od strane TQG strogog sistema kontrole kvaliteta. Planetarni zupčanici i sunčani zupčanici su svi spiralni zupčanici, naugljičeni i ugušeni na 58-62HRC, te će se nastaviti precizno brušenje i tehnička korekcija kako bi se postigao savršen prijenosni učinak. Planetarni zupčanik je podržan sa dva kraja igličastih valjaka, što je povećalo torzionu krutost. Nivo zaštite planetarnog mjenjača TQG je do međunarodnog standarda IP65 (potpuno otporan na prašinu i vodootporan).

Patent of PFR series Planetary Gear Reducers:

TQG PFR series planetary gearboxes are featured with two multi-national patent of lubricating construction, which is applied in the internal spiral gear structure to ensure the highest output efficient .

Patent 1: Smanjite aksijalni potisak rada planetarnog zupčanika.

Patent 2: Povećajte podmazivanje, smanjite otpor trenja i buku.

| Model No. | Jedinica | Stage | Ratio | PER040 | PER060 | PER080 | PER120 | PER160 |

| Nominalni izlazni moment | Nm | 1 | 3 | 17 | 28 | 112 | 165 | 423 |

| 4 | 15 | 38 | 110 | 146 | 364 | |||

| 5 | 14 | 40 | 108 | 160 | 423 | |||

| 7 | 13 | 35 | 105 | 149 | 358 | |||

| 10 | 12 | 25 | 100 | 141 | 293 | |||

| 2 | 15 | 17 | 28 | 112 | 165 | 423 | ||

| 20 | 15 | 38 | 110 | 146 | 364 | |||

| 25 | 14 | 40 | 108 | 160 | 423 | |||

| 30 | 13 | 28 | 112 | 165 | 423 | |||

| 35 | 13 | 35 | 105 | 149 | 358 | |||

| 40 | 12 | 38 | 110 | 146 | 364 | |||

| 50 | 14 | 40 | 108 | 160 | 423 | |||

| 70 | 13 | 35 | 105 | 149 | 358 | |||

| 100 | 12 | 25 | 100 | 141 | 293 | |||

| Maks. Izlazni moment | Nm | 1,2 | 3-100 | 3 puta normalnog izlaznog momenta | ||||

| Nominalna ulazna brzina | Rpm | 1,2 | 3-100 | 3000 | 3000 | 3000 | 3000 | 2500 |

| Maks. Ulazna brzina | Rpm | 1,2 | 3-100 | 5000 | 5000 | 5000 | 5000 | 3600 |

| Precizni zazor P1 | Arcmin | 1 | 3-10 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 |

| 2 | 12-100 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ||

| Standardni zazor P2 | Arcmin | 1 | 3-10 | ≤11 | ≤11 | ≤11 | ≤11 | ≤11 |

| 2 | 12-100 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ||

| Torziona krutost | Nm / arcmin | 1,2 | 3-100 | 3 | 6 | 12 | 22 | 50 |

| Maks. Radial Force | N | 1,2 | 3-100 | 320 | 460 | 1300 | 3200 | 6520 |

| Maks. Axial Force | N | 1,2 | 3-100 | 160 | 230 | 660 | 1600 | 3260 |

| Service Life | Hr | 1,2 | 3-100 | 20000hrs | ||||

| Efikasnost | % | 1 | 3-10 | ≥97% \ t | ||||

| 2 | 15-100 | ≥94% \ t | ||||||

| Težina | Kg | 1 | 3-10 | 0.73 | 0.99 | 2.1 | 4.98 | 18.2 |

| 2 | 15-100 | 1.05 | 1.46 | 3.2 | 6.92 | 24.9 | ||

| Radna temperatura | ℃ | 1,2 | 3-100 | ℃ -25 ℃ ~ + 90 | ||||

| Podmazivanje | 1,2 | 3-100 | Synthetic Grease | |||||

| Klasa zaštite | 1,2 | 3-100 | IP65 | |||||

| Mounting Position | 1,2 | 3-100 | Any Direction | |||||

| Nivo buke | dB (A) | 1,2 | 3-100 | ≤62 | ≤63 | ≤65 | ≤67 | ≤68 |

Moment of Inertia