Overview of PFR Speed Reducer

Overview of PFR Speed Reducer

● Square flange output design ensure fast connection with any motor

● High rigidity & torque due to the use of needle roller bearing

● Spiral bevel gears are adopted to ensure the lowest backlash

● Space-saving design

Motors can be mounted at a 90 degree to save the space

● No leakage of grease

High viscosity and non-separated grease is used to avoid the leakage.

● Square flange output design ensure fast connection with any motor

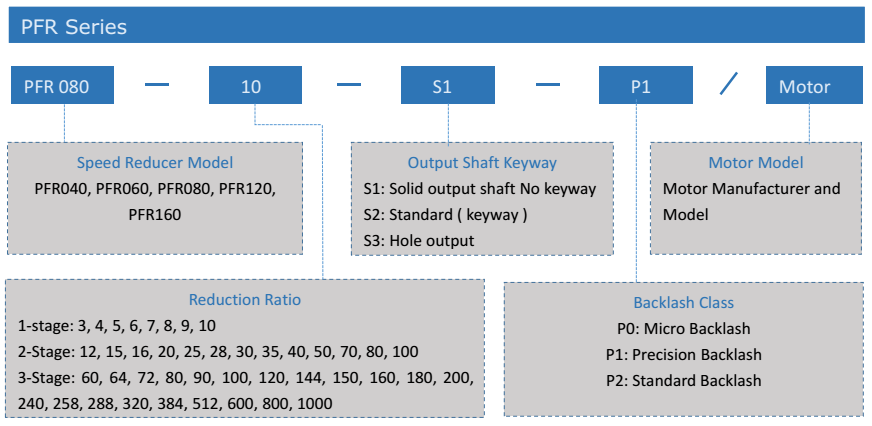

Indication of Model Numbers of PFR Speed Reducers

的描述 PFR Planetary Speed Reducer

PFR series right angle gearbox is designed for solve the problems of space. The compact structure of PFR speed reducer provides customer with a good solution when installation space or clearance are limited. High precision and solid construction make PFR speed reducer more valuable than other similar gearbox. Two ends of needle roller bearings with high precision on the shaft backup the planetary gears to improve the torsional stiffness of speed reducer. Meanwhile, this planetary gearbox is also an economy pecision gear reducer, providing an excellent choice for customers who has limited budget. In addition, flanged output design make it easier to connect with the equipment.

Application of PFR Precision Planetary Gearbox

Precision planetary reducer is widely used in various fields: environmental protection equipment, precision instruments, flame cutting, CNC machine tools, tool machinery, automation industry, printing machinery, textile printing and dyeing, pharmaceutical leather, environmental protection equipment, coal equipment, cement equipment, beer drink, mining machinery, wire rope transmission life test machine, glass equipment, winding machine, food packaging, welding equipment, CNC machine tools, laser cutting, industrial robot measuring equipment, rubber plastics, petrochemical, lifting transportation and other light and heavy industry, mechanical transmission and precision control field.

泰奇精工优质制造 Processes of PFR Planetary Gearbox:

所有组件均由TQG严格的质量控制系统控制。行星齿轮和太阳齿轮均采用斜齿轮,渗碳淬火至58-62HRC,并进行精密磨削和技术修正,以达到完美的传动效果。行星齿轮由滚针的两端支撑,这增强了扭转刚度。 TQG行星齿轮箱的防护等级达到国际标准IP65(全防尘和防水)。

Patent of PFR series Planetary Gear Reducers:

TQG PFR series planetary gearboxes are featured with two multi-national patent of lubricating construction, which is applied in the internal spiral gear structure to ensure the highest output efficient .

专利1:减少行星齿轮运行的轴向推力。

专利2:增加润滑,降低摩擦阻力和噪音。

| 型号。 | 单元 | 阶段 | 比 | PER040 | PER060 | PER080 | PER120 | PER160 |

| 额定输出扭矩 | 纳米 | 1 | 3 | 17 | 28 | 112 | 165 | 423 |

| 4 | 15 | 38 | 110 | 146 | 364 | |||

| 5 | 14 | 40 | 108 | 160 | 423 | |||

| 7 | 13 | 35 | 105 | 149 | 358 | |||

| 10 | 12 | 25 | 100 | 141 | 293 | |||

| 2 | 15 | 17 | 28 | 112 | 165 | 423 | ||

| 20 | 15 | 38 | 110 | 146 | 364 | |||

| 25 | 14 | 40 | 108 | 160 | 423 | |||

| 30 | 13 | 28 | 112 | 165 | 423 | |||

| 35 | 13 | 35 | 105 | 149 | 358 | |||

| 40 | 12 | 38 | 110 | 146 | 364 | |||

| 50 | 14 | 40 | 108 | 160 | 423 | |||

| 70 | 13 | 35 | 105 | 149 | 358 | |||

| 100 | 12 | 25 | 100 | 141 | 293 | |||

| 最大。输出扭矩 | 纳米 | 1,2 | 3-100 | 3倍正常输出扭矩 | ||||

| 额定输入速度 | 转 | 1,2 | 3-100 | 3000 | 3000 | 3000 | 3000 | 2500 |

| 最大。输入速度 | 转 | 1,2 | 3-100 | 5000 | 5000 | 5000 | 5000 | 3600 |

| 精密间隙P1 | 弧分 | 1 | 3-10 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 |

| 2 | 12-100 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ||

| 标准反冲P2 | 弧分 | 1 | 3-10 | ≤11 | ≤11 | ≤11 | ≤11 | ≤11 |

| 2 | 12-100 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ||

| 扭转刚性 | 牛米/弧分 | 1,2 | 3-100 | 3 | 6 | 12 | 22 | 50 |

| 最大。径向力 | ñ | 1,2 | 3-100 | 320 | 460 | 1300 | 3200 | 6520 |

| 最大。轴向力 | ñ | 1,2 | 3-100 | 160 | 230 | 660 | 1600 | 3260 |

| 使用寿命 | 人力资源 | 1,2 | 3-100 | 可达20000hrs | ||||

| 效率 | % | 1 | 3-10 | ≥97% | ||||

| 2 | 15-100 | ≥94% | ||||||

| 重量 | 公斤 | 1 | 3-10 | 0.73 | 0.99 | 2.1 | 4.98 | 18.2 |

| 2 | 15-100 | 1.05 | 1.46 | 3.2 | 6.92 | 24.9 | ||

| 工作温度 | ℃ | 1,2 | 3-100 | (-25℃~+90℃) | ||||

| 润滑 | 1,2 | 3-100 | 合成润滑脂 | |||||

| 保护等级 | 1,2 | 3-100 | IP65 | |||||

| 安装位置 | 1,2 | 3-100 | 任何方向 | |||||

| 噪音水平 | 分贝(A) | 1,2 | 3-100 | ≤62 | ≤63 | ≤65 | ≤67 | ≤68 |

Moment of Inertia