大致的了解 VRS 行星齿轮减速机

大致的了解 VRS 行星齿轮减速机

- Coaxial shaft design

- Standard mounting dimensions

- Broad frame sizes available

- High rigidity with large output torque

- High accuracy & Low backlash (1~3 arcmin)

- For servo motor and stepper motor

- Excelent performance and stablity

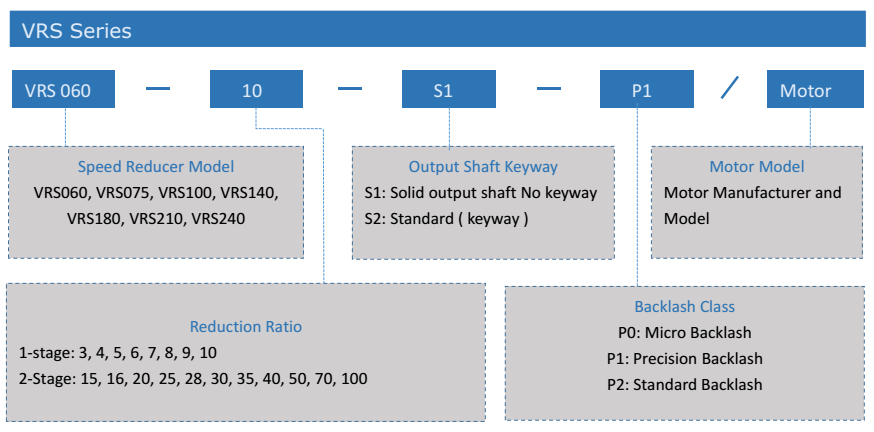

Indication of Model Numbers of VRS Speed Reducers

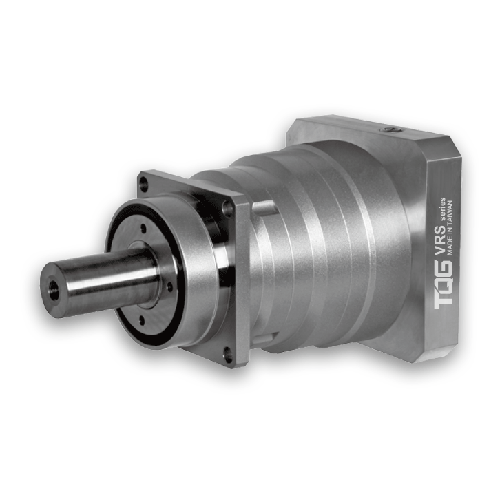

的描述 VRS High Precision Servo 变速箱

TQG high quality PAF series are inline servo speed reducer with a sturdy design and specially matched with stepper motor and servo motor, brands such like Panasonic, Yaskawa, Mitsubishi, Omron, Teco, Leadshine, etc. There are two optional backlash of VRS series planetary gearboxes: Micro precision backlash P0 (1~3 arcmin) and precision backlash P1 (3~5 arcmin). This planetary speed reducer has superior load capabilities, and is an ideal selection for higher speed and continuous duty applications. The tapered roller bearings at the output of the reducer gearbox allow the VRS reducer to handle larger radial and thrust loads. This internal design provides an extremely smooth and quiet running.

Application of VRS Planetary Reducers

As a recommended precision planetary servo gearbox, it is a perfect solution for extreme duty-operation for servo application, including gantries, printing equipment, packaging machinery, linear slides, loader robot, injection molding machines, food processing machinery, turret head, auto packing sealing machine, dispenser robot, or any other servo application that require high precision and large radial and thrust loading capacity.

| 型号。 | 单元 | 阶段 | 比 | VRS060 | VRS075 | VRS100 | VRS140 | VRS180 | VRS210 | VRS240 |

| 额定输出扭矩 | 纳米 | 1 | 3 | 55 | 130 | 208 | 342 | 586 | 1140 | 1500 |

| 4 | 50 | 140 | 290 | 542 | 1050 | 1700 | 2500 | |||

| 5 | 60 | 160 | 330 | 650 | 1200 | 2000 | 2500 | |||

| 6 | 55 | 150 | 310 | 600 | 1100 | 1900 | 2260 | |||

| 7 | 50 | 140 | 300 | 550 | 1100 | 1800 | 2300 | |||

| 8 | 45 | 120 | 260 | 500 | 1000 | 1600 | 2100 | |||

| 9 | 40 | 100 | 230 | 450 | 900 | 1500 | 1800 | |||

| 10 | 40 | 100 | 230 | 450 | 900 | 1500 | 1800 | |||

| 2 | 15 | 55 | 130 | 208 | 342 | 586 | 1140 | 2300 | ||

| 16 | 55 | 130 | 208 | 342 | 586 | 1140 | 2300 | |||

| 20 | 50 | 140 | 290 | 542 | 1050 | 1700 | 2500 | |||

| 25 | 60 | 160 | 330 | 650 | 1200 | 2000 | 2500 | |||

| 28 | 60 | 160 | 330 | 650 | 1200 | 2000 | 2500 | |||

| 30 | 55 | 150 | 310 | 600 | 1100 | 1900 | 2300 | |||

| 35 | 50 | 140 | 300 | 550 | 1100 | 1800 | 2200 | |||

| 40 | 45 | 120 | 260 | 500 | 1000 | 1600 | 2350 | |||

| 50 | 60 | 160 | 330 | 650 | 1200 | 2000 | 2200 | |||

| 70 | 50 | 140 | 300 | 550 | 1100 | 1800 | 2200 | |||

| 100 | 40 | 100 | 230 | 450 | 900 | 1500 | 1800 | |||

| 最大。输出扭矩 | 纳米 | 1,2 | 3-100 | 3倍正常输出扭矩 | ||||||

| 额定输入速度 | 转 | 1,2 | 3-100 | 5000 | 4000 | 4000 | 3000 | 3000 | 2000 | 1000 |

| 最大。输入速度 | 转 | 1,2 | 3-100 | 10000 | 8000 | 8000 | 6000 | 6000 | 4000 | 2500 |

| 微背隙P0 | 弧分 | 1 | 3-10 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 2 | 12-100 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| 精密间隙P1 | 弧分 | 1 | 3-10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 2 | 15-100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| 扭转刚性 | 牛米/弧分 | 1,2 | 3-100 | 7 | 14 | 25 | 50 | 145 | 225 | 260 |

| 最大。径向力 | ñ | 1,2 | 3-100 | 2750 | 4100 | 6400 | 9880 | 15000 | 20000 | 27500 |

| 最大。轴向力 | ñ | 1,2 | 3-100 | 2350 | 3200 | 5360 | 9690 | 14200 | 28000 | 30000 |

| 使用寿命 | 人力资源 | 1,2 | 3-100 | 可达20000hrs | ||||||

| 效率 | % | 1 | 3-10 | ≥96% | ||||||

| 2 | 15-100 | ≥93% | ||||||||

| 重量 | 公斤 | 1 | 3-10 | 1.8 | 3.8 | 7.2 | 16.8 | 32 | 49 | 65 |

| 2 | 15-100 | 2.1 | 4.1 | 8.1 | 17.5 | 35 | 53 | 70 | ||

| 工作温度 | ℃ | 1,2 | 3-100 | (-15℃〜+ 90℃) | ||||||

| 润滑 | 1,2 | 3-100 | 合成润滑脂 | |||||||

| 保护等级 | 1,2 | 3-100 | IP65 | |||||||

| 安装位置 | 1,2 | 3-100 | 任何方向 | |||||||

| 噪音水平 | 分贝(A) | 1,2 | 3-100 | ≤62 | ≤62 | ≤65 | ≤68 | ≤68 | ≤70 | ≤70 |

大致的了解 VRS 行星齿轮减速机

大致的了解 VRS 行星齿轮减速机