Superrigardo de DE Mandrel Flange Type Cam Indexer

- Compact structure & small size: it made of only one cam and an output turret without other unnecessary parts.

- Smooth operation & no noise: the output turret can rotate at any position to realize the transmission running smoothly without vibration and noise.

- High precision indexing & positioning self locking: due to adopts the special designed cam roller, it can maintain high segmentation accuracy and high torque to ensure the ability of heavy load.

- High speed performance & high torque: preloading on the taper support rib of cam and cam roller to avoid the generation of gap, so as to make the operation reliable and high speed, and reduces the impact force produced by the load or vibration.

- Maintenance free & long life: except for replacing lubricating oil, there is no need for maintenance when the usage time below 100000 hours.

Descriptions of DE Mandrel Flange Type Cam Indexer

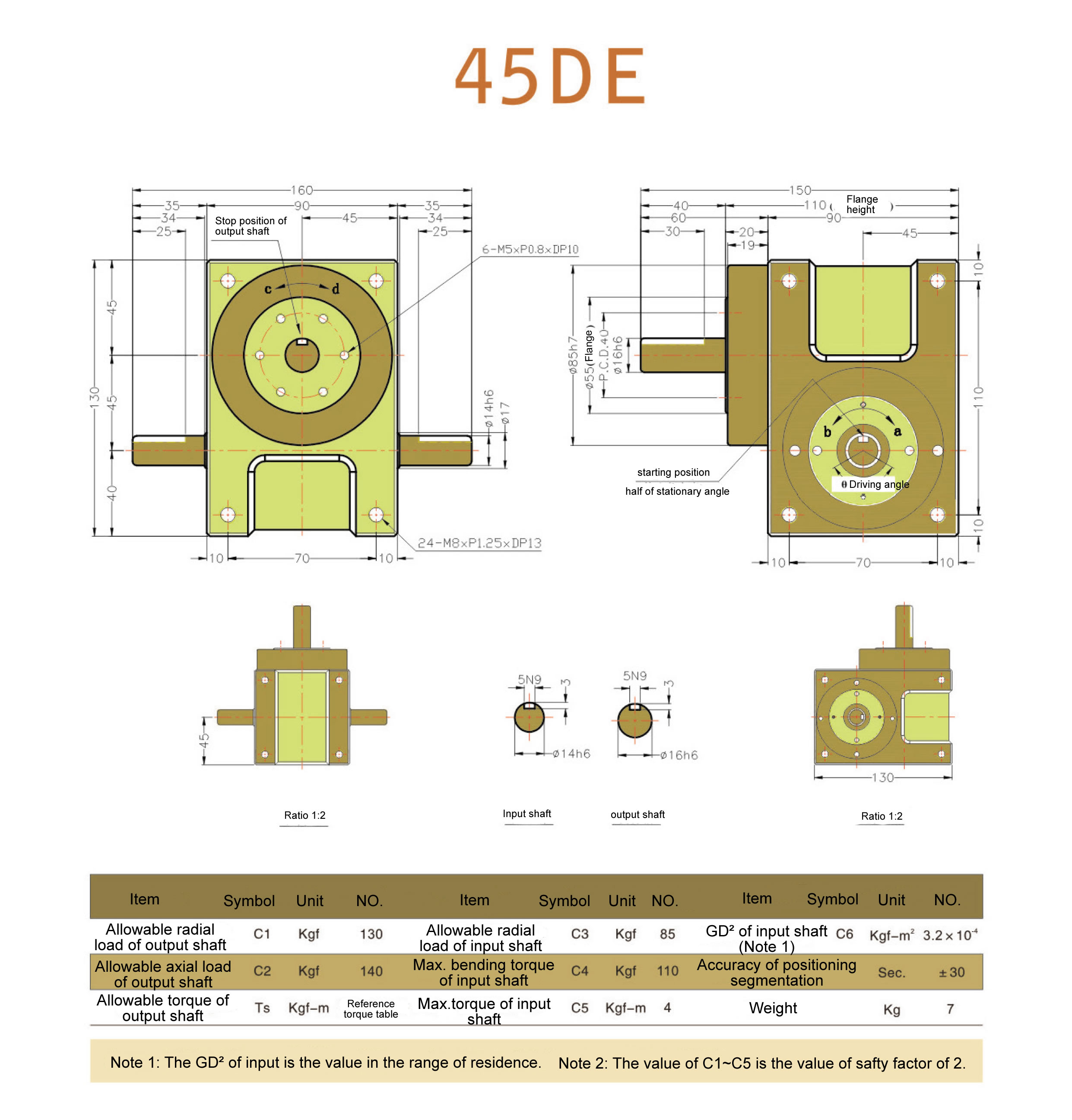

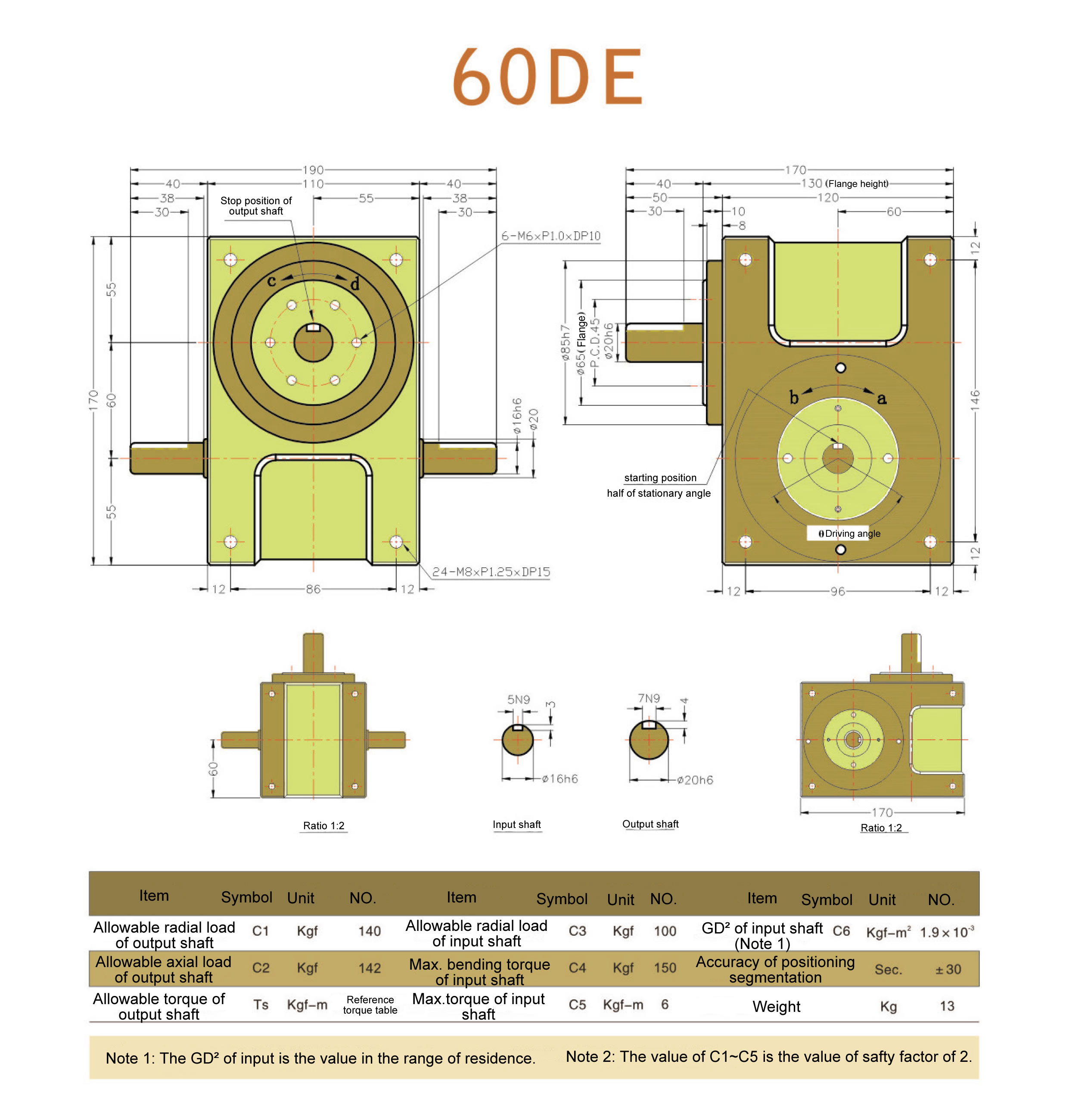

Cam Indexer, also called cam splitter, intermittent divider. It is a high precision rotary device. The DE mandrel flange type cam indexer not only has the advantages of high accuracy, high reliability, high speed and high durability, but also provides a clearer and simpler mounting surface. The output shaft type of this series of products are various, shaft type and flange type are available, so that the accessories (such as worktable, pendulum arm or sprocket) are easy to install. The cam indexer use advanced lubricating oil to lubricate the products, so as to realize the lifetime free maintenance of the products.

DE mandrel flange type cam indexer can be used in electronic, mechanical, medical, building, food and other industries.

Operation Principle

The structure of the cam indexer is that the cam mounted on the input shaft is engaged with the needle bearing, which fixed on the indexing shaft of the output shaft. The needle roller bearings embedded on the circumferential surface of the indexing plate are linearly contacted with the corresponding inclined planes of the cam.

When the input axis rotates, the cam turns according to the given displacement curve. When the two groups of needle bearings are riding on the straight line of the cam, it also means the needle roller bearings rotate in the static range, but the indexing plate does not rotate.

When the cam is rotated to the curve position, and the two cam roller contacts are usually converted to three cam rollers, so that the rotation of the output axis can transfer the force evenly to the output axis.

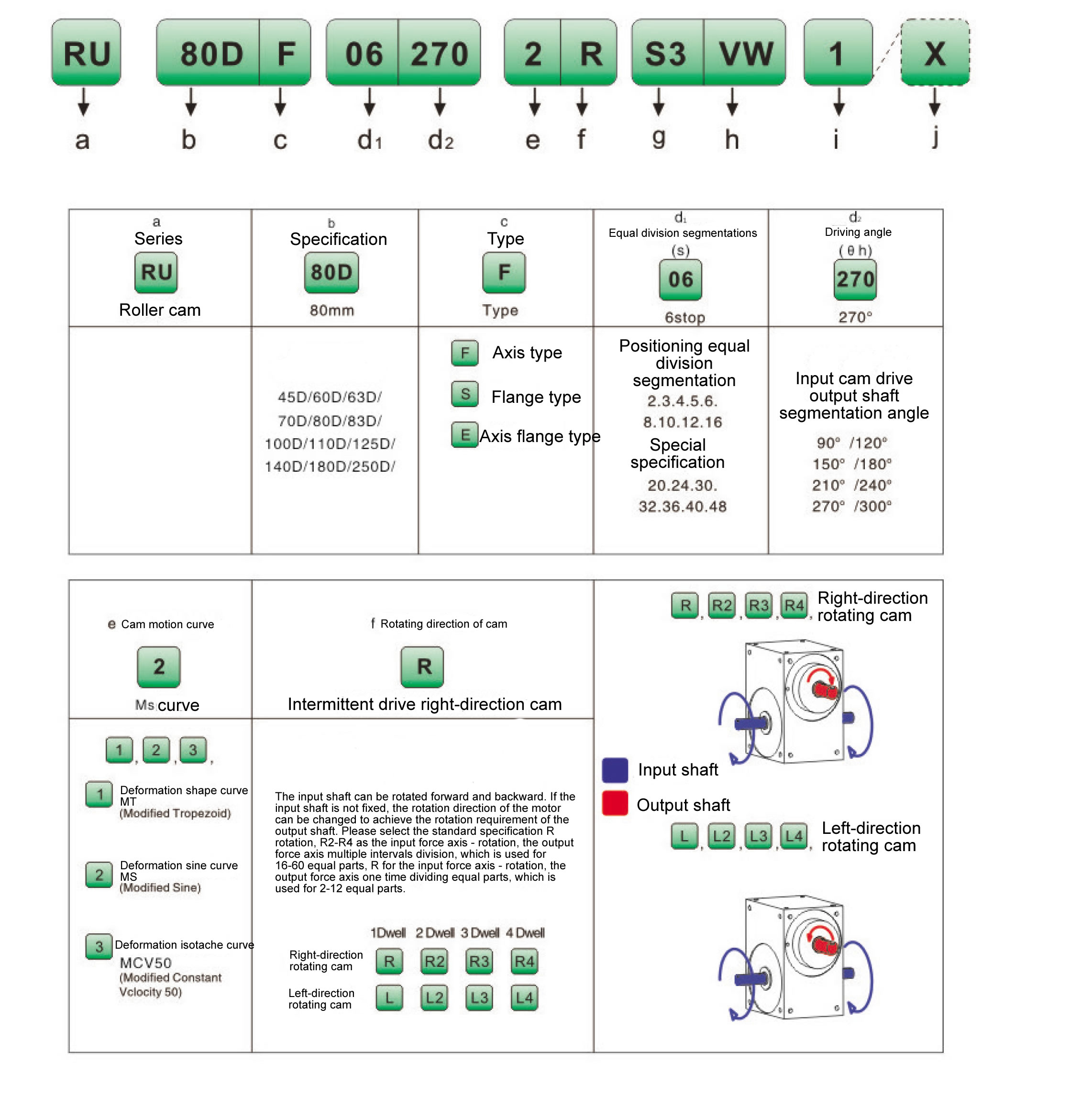

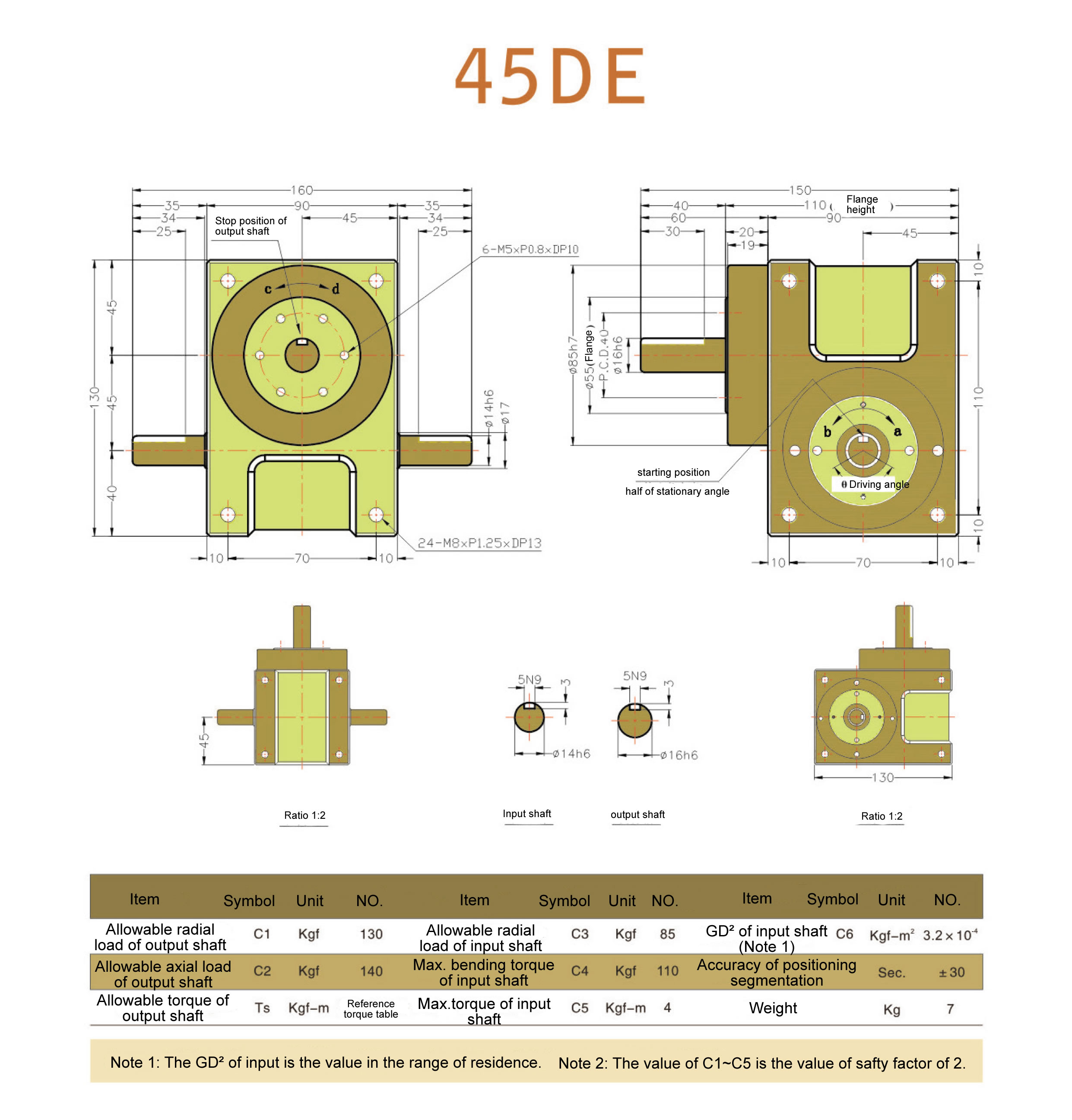

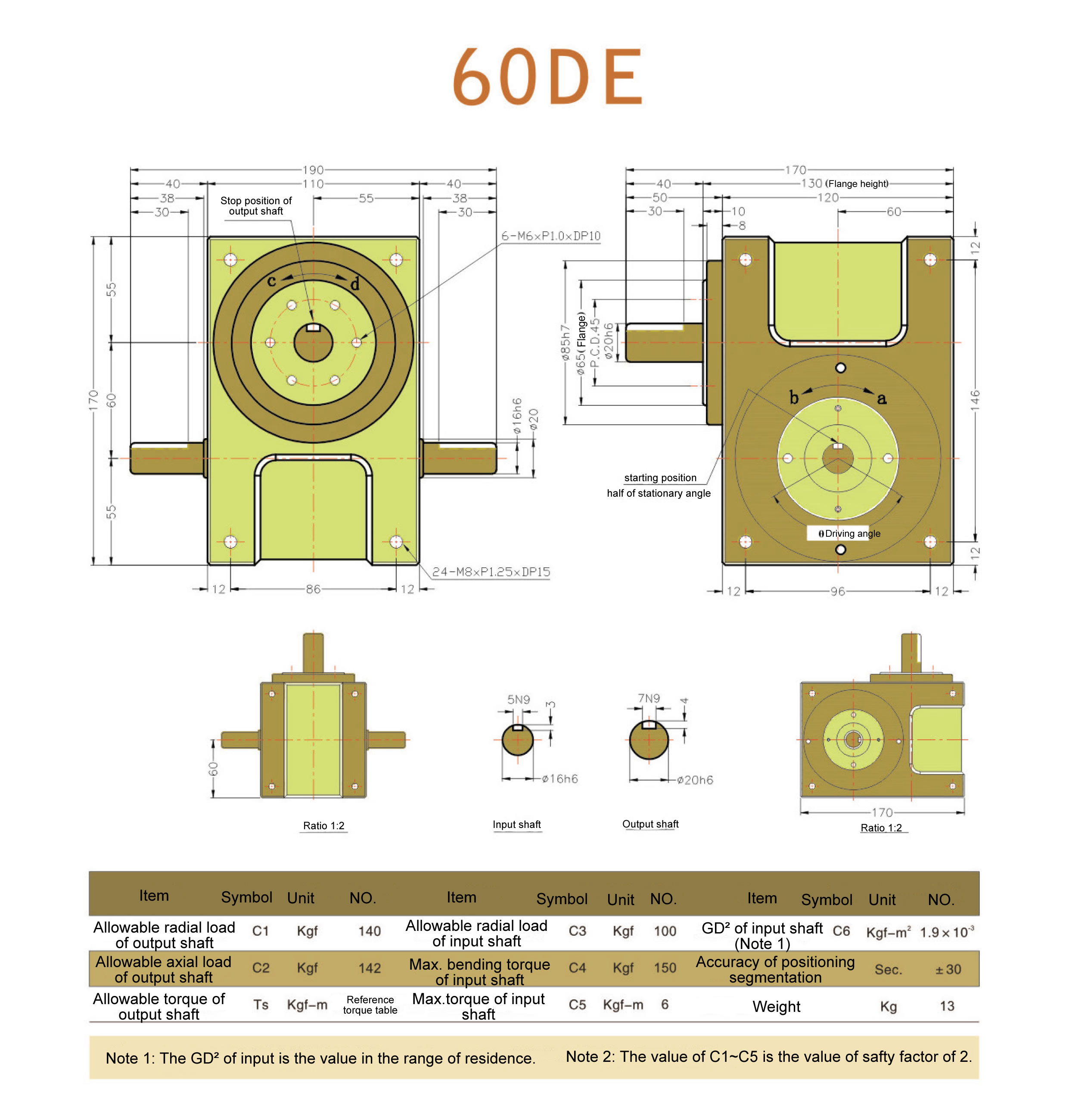

Indiko de Modelaj Numeroj de DE Mandrel Flange Type Cam Indexer