Overview of PFR Speed Reducer

Overview of PFR Speed Reducer

● Square flange output design ensure fast connection with any motor

● High rigidity & torque due to the use of needle roller bearing

● Spiral bevel gears are adopted to ensure the lowest backlash

● Space-saving design

Motors can be mounted at a 90 degree to save the space

● No leakage of grease

High viscosity and non-separated grease is used to avoid the leakage.

● Square flange output design ensure fast connection with any motor

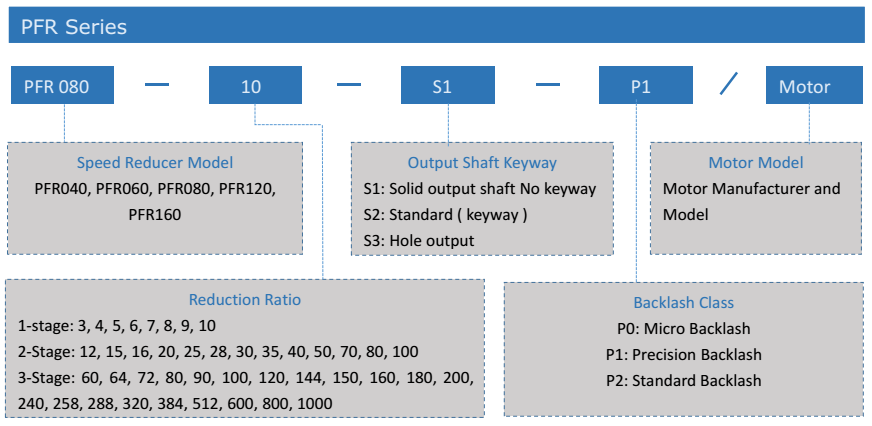

Indication of Model Numbers of PFR Speed Reducers

Deskribapena PFR Planetary Speed Reducer

PFR series right angle gearbox is designed for solve the problems of space. The compact structure of PFR speed reducer provides customer with a good solution when installation space or clearance are limited. High precision and solid construction make PFR speed reducer more valuable than other similar gearbox. Two ends of needle roller bearings with high precision on the shaft backup the planetary gears to improve the torsional stiffness of speed reducer. Meanwhile, this planetary gearbox is also an economy pecision gear reducer, providing an excellent choice for customers who has limited budget. In addition, flanged output design make it easier to connect with the equipment.

Application of PFR Precision Planetary Gearbox

Precision planetary reducer is widely used in various fields: environmental protection equipment, precision instruments, flame cutting, CNC machine tools, tool machinery, automation industry, printing machinery, textile printing and dyeing, pharmaceutical leather, environmental protection equipment, coal equipment, cement equipment, beer drink, mining machinery, wire rope transmission life test machine, glass equipment, winding machine, food packaging, welding equipment, CNC machine tools, laser cutting, industrial robot measuring equipment, rubber plastics, petrochemical, lifting transportation and other light and heavy industry, mechanical transmission and precision control field.

Taiqi Seiko Superior Manufacturing Processes of PFR Planetary Gearbox:

Osagai guztiak TQG kalitate kontroleko sistema zorrotza kontrolatzen dute. Engranaje planetarioak eta eguzki engranaje helikoidale guztiak dira, 58-62HRC 58 eta 62 HRC arte, eta doitu egingo dira doitasun eta artezketa teknikoak zuzendutako transmisio efektu ezin hobea lortzeko. Planetako engranaje orratzaren bi muturrekin babesten da, hau da, torsio zurruntasuna hobetu du. TQG planetako kaxen babes-maila nazioarteko estandarra da IP65rako (guztiz antzera eta iragazgaitza).

Patent of PFR series Planetary Gear Reducers:

TQG PFR series planetary gearboxes are featured with two multi-national patent of lubricating construction, which is applied in the internal spiral gear structure to ensure the highest output efficient .

Patentea 1: Murriztu planetaren engranaje planetaren ardatz axiala.

Patentea 2: Handitu lubrifikazioa, murriztu marruskadura erresistentzia eta zarata.

| Modeloaren zenbakia | unitatea | Stage | Ratio | PER040 | PER060 | PER080 | PER120 | PER160 |

| Ebaluatutako irteera momentua | nm | 1 | 3 | 17 | 28 | 112 | 165 | 423 |

| 4 | 15 | 38 | 110 | 146 | 364 | |||

| 5 | 14 | 40 | 108 | 160 | 423 | |||

| 7 | 13 | 35 | 105 | 149 | 358 | |||

| 10 | 12 | 25 | 100 | 141 | 293 | |||

| 2 | 15 | 17 | 28 | 112 | 165 | 423 | ||

| 20 | 15 | 38 | 110 | 146 | 364 | |||

| 25 | 14 | 40 | 108 | 160 | 423 | |||

| 30 | 13 | 28 | 112 | 165 | 423 | |||

| 35 | 13 | 35 | 105 | 149 | 358 | |||

| 40 | 12 | 38 | 110 | 146 | 364 | |||

| 50 | 14 | 40 | 108 | 160 | 423 | |||

| 70 | 13 | 35 | 105 | 149 | 358 | |||

| 100 | 12 | 25 | 100 | 141 | 293 | |||

| Max. Irteera momentua | nm | 1,2 | 3-100 | 3 irteerako pare normalaren denbora | ||||

| Balioztatutako sarrera abiadura | rpm | 1,2 | 3-100 | 3000 | 3000 | 3000 | 3000 | 2500 |

| Max. Sarrera abiadura | rpm | 1,2 | 3-100 | 5000 | 5000 | 5000 | 5000 | 3600 |

| Zehaztasun atzeraezina P1 | Arcmin | 1 | 3-10 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 |

| 2 | 12-100 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ||

| Errebelazio P2 estandarra | Arcmin | 1 | 3-10 | ≤11 | ≤11 | ≤11 | ≤11 | ≤11 |

| 2 | 12-100 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ||

| Torsional zurruntasuna | Nm / arcmin | 1,2 | 3-100 | 3 | 6 | 12 | 22 | 50 |

| Max. Indar erradiala | N | 1,2 | 3-100 | 320 | 460 | 1300 | 3200 | 6520 |

| Max. Axial Force | N | 1,2 | 3-100 | 160 | 230 | 660 | 1600 | 3260 |

| Zerbitzuaren bizitza | hr | 1,2 | 3-100 | 20000hrs | ||||

| Eraginkortasuna | % | 1 | 3-10 | % ≥97 | ||||

| 2 | 15-100 | % ≥94 | ||||||

| pisu | Kilogramo | 1 | 3-10 | 0.73 | 0.99 | 2.1 | 4.98 | 18.2 |

| 2 | 15-100 | 1.05 | 1.46 | 3.2 | 6.92 | 24.9 | ||

| Eragiketa tenperatura | ℃ | 1,2 | 3-100 | (-25℃~+90℃) | ||||

| lubrifikazio | 1,2 | 3-100 | Gantz sintetikoa | |||||

| Babes Klasa | 1,2 | 3-100 | IP65 | |||||

| Muntatzeko posizioa | 1,2 | 3-100 | Edozein zuzendaritza | |||||

| Zarata maila | dB (A) | 1,2 | 3-100 | ≤62 | ≤63 | ≤65 | ≤67 | ≤68 |

Moment of Inertia