Yleiskatsaus Screw Driven Linear Slide

- Advanced processing technology

- Imported high quality material

- High repeated positioning accuracy

- Space-saving with a simple structure

- Low noise & rust-proof

Descriptions of Screw Driven Linear Slide

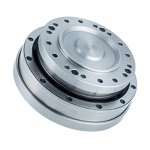

The screw driven liner slide of TQG adopts modular design with ball screw, linear guide rail, aluminum alloy profile, ball screw holder, coupling, motor and photoelectric switch. The linear slide is a kind of mechanical structure which provide linear motion and it could be used horizontally or vertically. The Taiqi screw driven linear slide is usually used in conjunction with the power motor. Other workpieces are installed on the slider to form a complete conveying and moving device and a suitable motor reversing program is set up to enable the workpiece to work automatically and repeatedly and the purpose of mass production and intensive production could be achieved.

Ominaisuudet Screw Driven Linear Slide

- The base of the TQG screw driven linear slideadopts an integrated structure with extruded aluminum profile.

- The power developed by the screw driven liner slideis transmitted by the ball screw and multi positioning and multistratum control could be realized. The repeat positioning accuracy can be achieved + 0.01~ + 0.02mm.

- The screw driven linear slide has good adaptability and it couldbe matched with a variety of motor and motor control regulators.

- The screw driven linear slidecould be matched with suitable accessories to improve the assembly efficiency.

Applications

The screw driven linear slide of Taiqi Seiko is widely used in reciprocating spraying machine, printing equipment, mechanical arm, packaging machine, chemical product equipment, food equipment, metal processing equipment, textile machinery, woodworking equipment, load shifting equipment, automatic dispensing equipment, automatic processing equipment workpiece positioning equipment, labeling machine, laser cutting and positioning equipment, water cutting and positioning equipment, ultrasonic welding positioning equipment, ultrasonic welding location setting. equipment, medical equipment, solar equipment, injection molding machine, precision machine tools and pharmaceutical machinery.