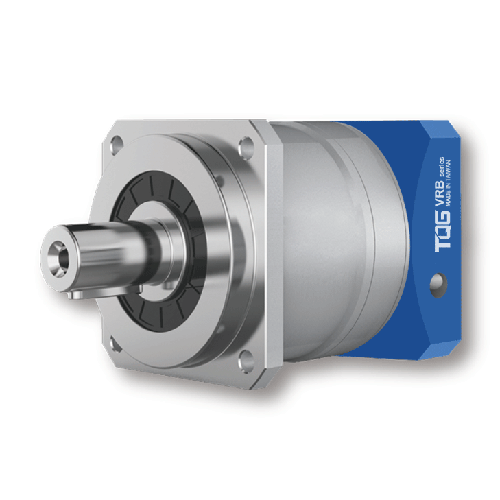

Ringkesan VRB Speed Reducer

- Struktur integral saka bingkai dinding planet lan poros output njamin kaku maksimum lan kestabilan.

- Retno paling murah 0-2 arcmin matur nuwun kanggo mesin panggeser presisi sing dhuwur.

- Metode output flange kothak kanggo entuk koneksi cepet karo motor apa wae.

- Efisiensi tinggi 95% amargi derajat meshing dhuwur saka gear rigiditas dhuwur

- Penyelenggaraan gratis amarga umur lemak grease sintetik umur.

Gambaran saka VRB High Precision Plan dhasar Gearboxes:

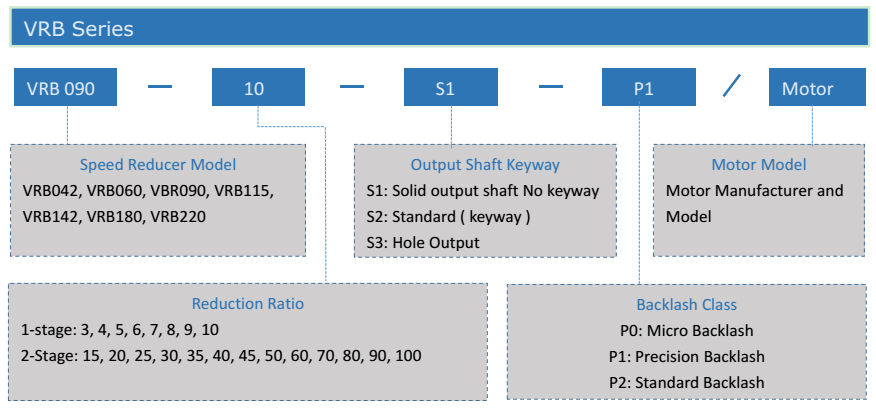

Taiqi Seiko fokusake kanggo ngembangake teknologi presisi gear kangge nyukupi kabutuhan konsumen ing bidang otomasi industri. Serial Taiqi Seiko VRB yaiku karya riset lan pangembangan kita. We offer gearboxes series VRB kanthi pilihan paling komprehensif ukuran frame lan rasio abang lan bisa cocok kanggo konfigurasi sing beda. Dimensi pemasangan standar industri ngidini Taiqi VRB bisa adaptasi karo desain peralatan sing beda, nyimpen wektu lan dhuwit pelanggan. Garis VRB seri gearboxes dhuwur ing planet iku produk padha karo seri PAB. Dibandhingake karo bingkai bentuk persegi PAB, seri gearboxe planet VRB dirancang kanthi wujud bunder. Iku kabeh gearboxes inline. PAB Precision reducers wis wates kisaran watesan kanggo pilih. Gearboxing planet VRB mung duwe rong pilihan reaksi sing dipilih kanggo sampeyan: Backlash mikroelektronik presisi (P0) lan backlash presisi (P1), tanpa standar backlash presisi standar (P2). Ing aspek ukuran lan torsi, ana prabédan cilik. Gearboxing planet VRB uga nawakake ukuran sing wiyar kanggo pilihan, sing bisa ketemu karo kabutuhan aplikasi sing beda-beda. Kanggo rincian liyane, mangga dipriksa halaman katalog sing gegandhengan. Taiqi VRB Series gearboxes planet sing ditrapake kanggo motor servo lan motor stepper merek kaya Panasonic, Fanuc, SIEMENS, Matsushita, Mitsubishi, Lenz, Yaskawa, lan liya-liyane.

Analisis Grafik VRB High Precision Plan dhasar Gearboxes

Aplikasi saka VRB High Precision Plan dhasar Pengurang:

Taqi Seiko VRB High Precision Planetary reducers adalah solusi sampurna kanggo aplikasi servomotor, sing akeh digunakake ing mesin polishing, peralatan kertas, peralatan energi surya, mesin pemotong CNC, peralatan kaca, mesin bending pipa, peralatan mobil, mesin reciprocating, mesin engraving, mesin jahit, aluminium langsir pintu lan jendela peralatan, mesin injeksi molding, peralatan papan sirkuit, peralatan perlengkapan, peralatan eksperimental, mesin coating, instrumen uji presisi, universitas riset ilmiah Institut, dll.

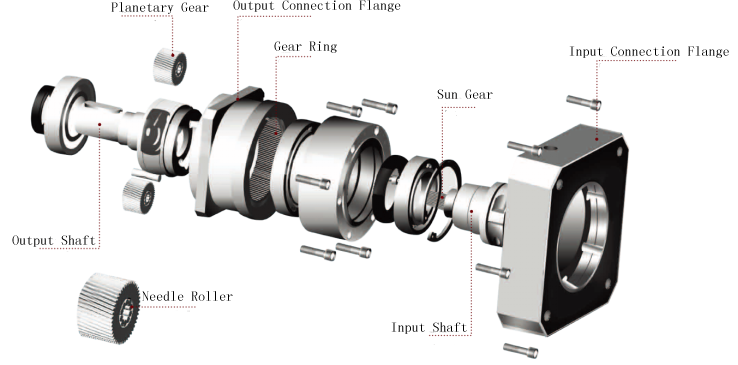

Taiqi Seiko Superior Manufacturing Processes saka VRB Planetary Gearbox:

Kabeh komponen dikontrol dening sistem kontrol kualitas apik TQG. Gears planet lan gear matahari kabeh gear helical, carburized lan quenched kanggo 58-62HRC, lan bakal dileksanakake Precision grinding lan technical dibenakake kanggo entuk efek transmisi sampurna. Gear planet iki didhukung dening rong ujung roller jarum, sing nambah kekuwatan torsi. Tingkat proteksi saka gearbox planet TQG nganti standar internasional IP65 (tahan debu lan tahan banyu).

Paten saka PAB series Planetary Gear Reducers:

Seri TQG PAB seri gearboxes ditampilake karo rong paten paten multi konstruksi patrikan, sing diterapake ing struktur gear spiral internal kanggo njamin output paling efisien.

Paten 1: Ngurangi tujuwan aksial saka gear planetary mlaku.

Paten 2: Nambah lubrication, nyuda resistensi lan swara gesekan.

| Model No. | Unit | Tahap | Rasio | VRB042 | VRB060 | VRB090 | VRB115 | VRB142 | VRB180 | VRB220 |

| Nilai Output Torque | Nm | 1 | 3 | 20 | 55 | 130 | 208 | 342 | 588 | 1140 |

| 4 | 19 | 50 | 140 | 290 | 542 | 1050 | 1700 | |||

| 5 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 6 | 20 | 55 | 150 | 310 | 600 | 1100 | 1900 | |||

| 7 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 8 | 17 | 45 | 120 | 260 | 500 | 1000 | 1600 | |||

| 9 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 10 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 2 | 15 | 20 | 55 | 130 | 208 | 342 | 588 | 1140 | ||

| 20 | 19 | 50 | 140 | 290 | 542 | 1050 | 1700 | |||

| 25 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 30 | 20 | 55 | 150 | 310 | 600 | 1100 | 1900 | |||

| 35 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 40 | 17 | 45 | 120 | 260 | 500 | 1000 | 1600 | |||

| 45 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 50 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 60 | 20 | 55 | 150 | 310 | 600 | 1100 | 1900 | |||

| 70 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 80 | 17 | 45 | 120 | 260 | 500 | 1000 | 1600 | |||

| 90 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 100 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| Maks. Output Torque | Nm | 1,2 | 3-100 | 3 Kaping Output Normal Torsi | ||||||

| Rated Input Rated | Rpm | 1,2 | 3-100 | 5000 | 5000 | 4000 | 4000 | 3000 | 3000 | 2000 |

| Maks. Input Speed | Rpm | 1,2 | 3-100 | 10000 | 10000 | 8000 | 8000 | 6000 | 6000 | 4000 |

| Micro Backlash P0 | Arcmin | 1 | 3-10 | ≤ 2 | ≤ 2 | ≤ 2 | ≤ 2 | ≤ 2 | ≤ 2 | ≤ 2 |

| 2 | 12-100 | ≤ 4 | ≤ 4 | ≤ 4 | ≤ 4 | ≤ 4 | ≤ 4 | ≤ 4 | ||

| Precision Backlash P1 | Arcmin | 1 | 3-10 | ≤ 4 | ≤ 4 | ≤ 4 | ≤ 4 | ≤ 4 | ≤ 4 | ≤ 4 |

| 2 | 12-100 | ≤ 6 | ≤ 6 | ≤ 6 | ≤ 6 | ≤ 6 | ≤ 6 | ≤ 6 | ||

| Torsional Rigidity | Nm / arcmin | 1,2 | 3-100 | 3 | 7 | 14 | 25 | 50 | 145 | 225 |

| Maks. Radial Force | N | 1,2 | 3-100 | 780 | 1530 | 3250 | 6700 | 9400 | 14500 | 50000 |

| Maks. Angkatan Aksial | N | 1,2 | 3-100 | 350 | 630 | 1300 | 3000 | 4000 | 6200 | 35000 |

| Layanan urip | Hr | 1,2 | 3-100 | 20000hrs | ||||||

| Efficiency | % | 1 | 3-10 | ≥97% | ||||||

| 2 | 15-100 | ≥ 94% | ||||||||

| Bobot | Kg | 1 | 3-10 | 0.5 | 1.3 | 3.3 | 7.8 | 15 | 28 | 52 |

| 2 | 15-100 | 0.8 | 1.48 | 3.9 | 9.6 | 18.9 | 33 | 66 | ||

| Temp operasi. | ℃ | 1,2 | 3-100 | (-15 ℃ ~ + 90 ℃) | ||||||

| Lubrication | 1,2 | 3-100 | Grease sintetik | |||||||

| Proteksi Kelas | 1,2 | 3-100 | IP65 | |||||||

| Posisi Gunung | 1,2 | 3-100 | Sembarang Arah | |||||||

| Tingkat kebak | dB (A) | 1,2 | 3-100 | ≤56 | ≤58 | ≤ 60 | ≤63 | ≤65 | ≤67 | ≤ 70 |