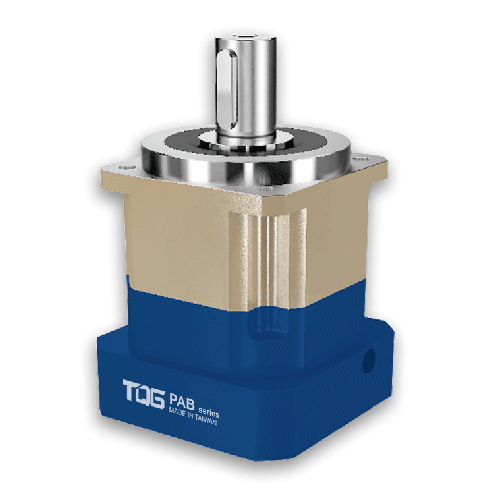

ພາບລວມຂອງ PAB Planetary Gear Reducer

ພາບລວມຂອງ PAB Planetary Gear Reducer

- Lowest backlash of 0-3 arcmin.

- High torque and high dynamic.

- High cost performance.

- Applicable for all servo motor and stepper motor.

- Improve the rigidity and increase the motor rotor inertia.

- Shorten the positioning time of starting and stopping

- Miniaturization of motor power. At the same time, improve the stability of inertia load and reduce the vibration.

- The surface of the gear box is treated with electroless Nickel, and the connection plate is treated with blue anode to improve the tolerance and corrosion resistance of the environment.

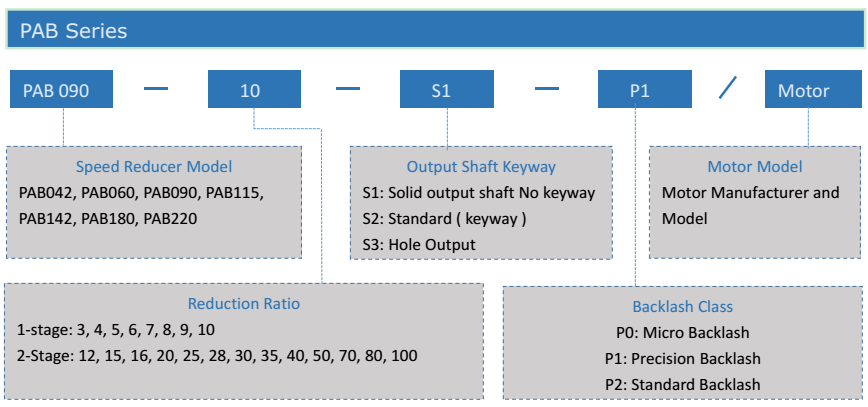

Indication of Model Numbers of PAB Speed Reducers

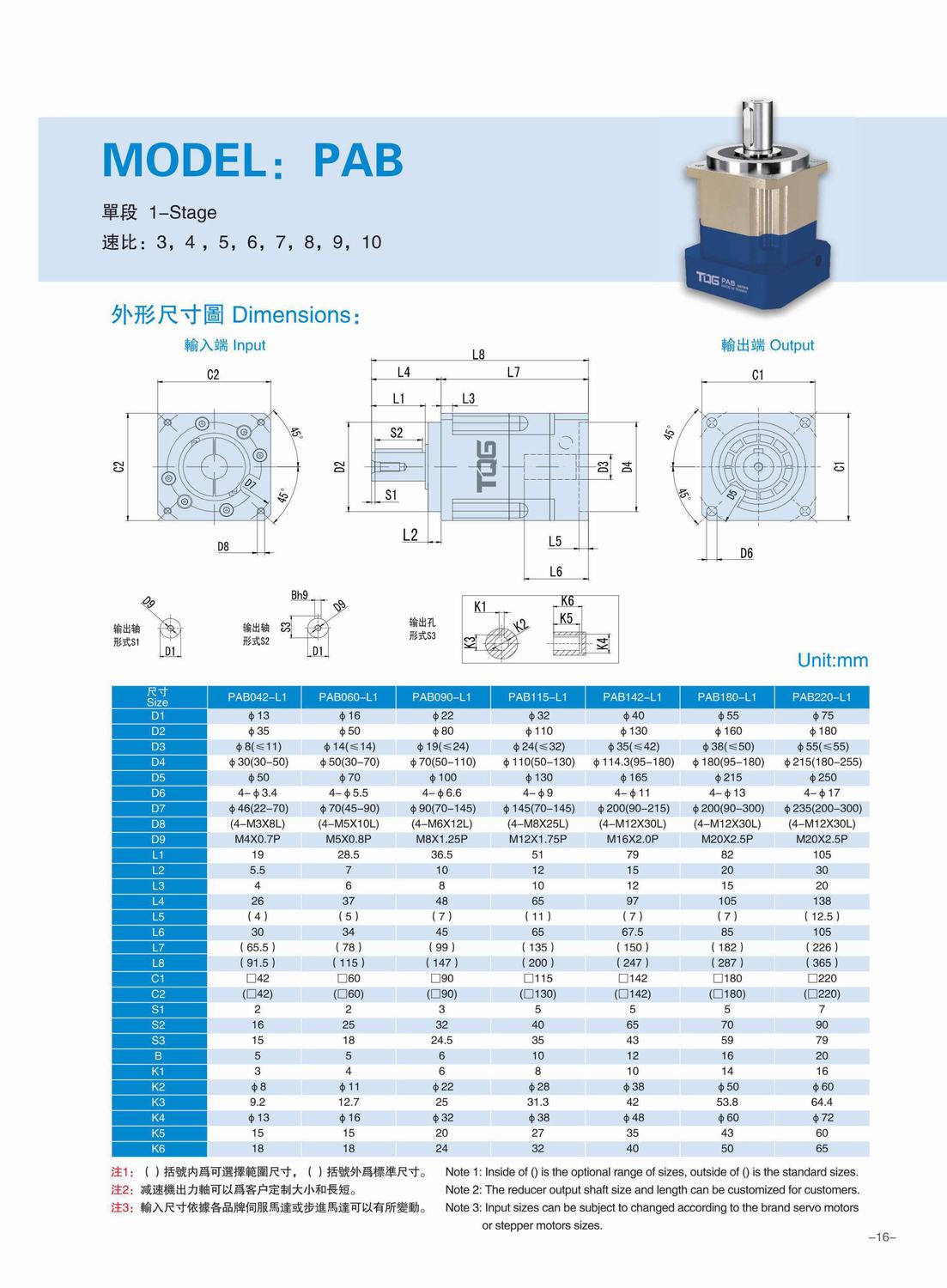

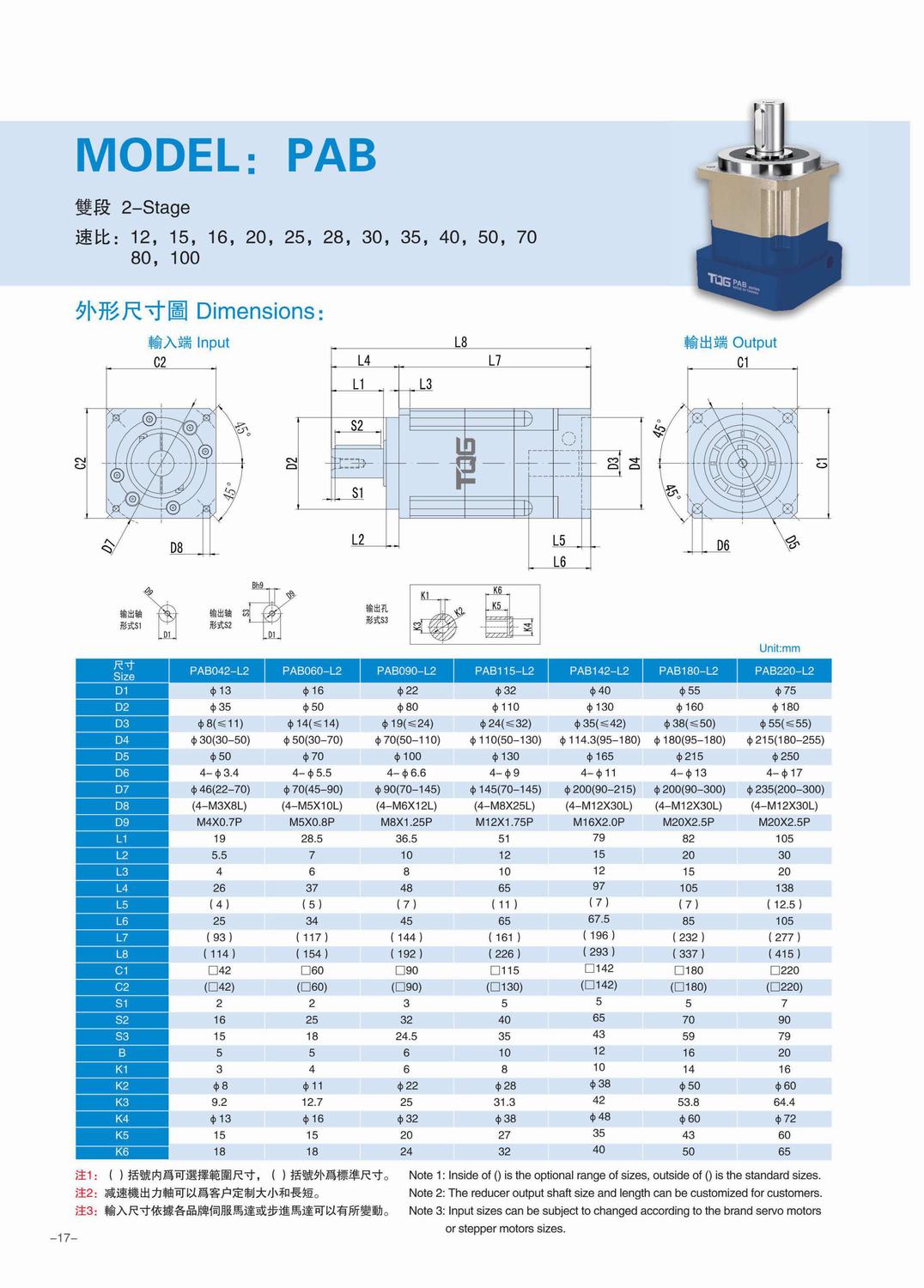

ລາຍລະອຽດຂອງ PAB High Precision Planetary Gearboxes

Taiqi Seiko PAB series high precision planetary gearboxes consists of a complete sizes of inline gearboxes also called Coaxial gearboxes. There are three optional backlash PAB planetary gearboxes for choice: Micro precision backlash (P0), precision backlash (P1) and standard backlash (P2), which are featured with outstanding performance and widely applied in motion control industries for servo application. Taiqi Seiko PAB precision gearboxes are featured with high torque and the input stepper diameter D4 can be up toφ255mm, which can greatly meet the customer needs of high torque. Single-stage planetary gearboxes and two-stage gearboxes for selection according to your application needs.

- stage reduction ratio : 3, 4, 5, 6, 7, 8, 9, 10

- Stage reduction ratio: 12, 15, 20, 25, 30, 35, 40, 50, 60, 70, 80, 90, 100

Note:Three-stage technical data are not available in Taiqi Seiko catalogue. If needed, please contact our sales person.

Application of PAB High Precision Planetary Reducers:

Taiqi Seiko PAB High Precision Planetary Gearboxes are extensively applied in the aviation industry, spaceflight, ship, radar, submarine, food machinery, medical machinery, women’s supplies machinery, composite materials. Equipment, precision testing instruments, data communication system, robot, mechanical arm, CNC machine tool, cutting and welding equipment, laser system, textile machinery, printing and dyeing machinery, packaging machinery, printing machinery, testing machines, stamping technology, plastic machinery, glass machinery, lifting machinery, metallurgical machinery, engineering machinery and University Scientific Research Institute and so on.

Configurations of PAB Planetary Gearbox

- The housing and flange of Taiqi Seiko gearbox are made of Aluminum alloy die-casting ADC12

- Planetary gear systems are made of high precision gears

- The material of Ring Gearsis 40Cr

- Planetary gears’ material of PAB precision gearbox is 20CrMnTi,the surface hardnessvalue of PAB planetary reducer is about HRC58~62 , and the inner hardness data is around HRC33~40

- Input end of gearbox is equipped with motor adaptorand keyed hollow shaft

- Output configurations of Taiqi PAB speed reducer are keyed solid shaft-outputmethod, Keyless Solid Shaft Outputor output for holes. It depends on the specific needs of customers.

- Applicable motorsare servo motorsand stepper motors for all Japanese, German, Taiwan or American brands.

Why Choose TQG PAB Planetary Gearboxes for your precision application?

- Finite element analysis of gear strength is carried out by using ANSYS technology. Tooth profile and lead trimming of tooth surface are also made to reduce the impact and noise of gear meshing, and increase the service life of gear system.

- Carbon-nitridingheat-treated high quality alloy steel is adopted in gear materials to obtain the best wear resistance and impact toughness.

- The output planet carrier adopts integral (double support) structure design. The large span of the front and rear bearings is distributed inside the box body, forming a stable integrated structure to ensure high torsion rigidity and accuracy.

- An integrated design of the tooth ring and the output shell is adopted, and high quality steel is used to get high material density by hot forging. The integrated design can ensure that all geometric dimensions are finished in one time and have higher precision and strength compared with other embedded and clamped structures.

- The input shaft and locking device are designed in an integrated way. The two bolts are symmetrically distributed to achieve dynamic balance. At the same time, through the strong locking of double bolts, the motor shaft transmission is effectively prevented from slipping and the high-precision zero backlash power transmission is achieved.

| Model No. | Unit | Stage | Ratio | PAB042 | PAB060 | PAB090 | PAB115 | PAB142 | PAB180 | PAB220 |

| Rated Output Torque | Nm | 1 | 3 | 19 | 56 | 148 | 280 | 520 | 1020 | 1550 |

| 4 | 20 | 55 | 160 | 330 | 580 | 1280 | 2160 | |||

| 5 | 21 | 58 | 159 | 330 | 580 | 1250 | 2100 | |||

| 6 | 16 | 48 | 120 | 240 | 410 | 980 | 1350 | |||

| 7 | 19 | 50 | 148 | 300 | 530 | 1030 | 1580 | |||

| 8 | 13 | 45 | 130 | 230 | 450 | 880 | 1260 | |||

| 9 | 12 | 40 | 100 | 220 | 410 | 880 | 1450 | |||

| 10 | 15 | 46 | 125 | 260 | 475 | 950 | 1530 | |||

| 2 | 12 | 18 | 52 | 155 | 300 | 530 | 1100 | 1750 | ||

| 15 | 18 | 53 | 150 | 280 | 550 | 1050 | 1650 | |||

| 16 | 20 | 53 | 158 | 320 | 580 | 1200 | 2050 | |||

| 20 | 20 | 52 | 155 | 320 | 580 | 1200 | 2050 | |||

| 25 | 19 | 52 | 158 | 320 | 580 | 1200 | 2000 | |||

| 28 | 19 | 50 | 150 | 300 | 550 | 1100 | 1850 | |||

| 30 | 18 | 49 | 145 | 390 | 500 | 1050 | 1600 | |||

| 35 | 17 | 48 | 155 | 290 | 500 | 1020 | 1500 | |||

| 40 | 18 | 48 | 150 | 290 | 530 | 1100 | 1350 | |||

| 50 | 18 | 50 | 145 | 290 | 530 | 1000 | 1300 | |||

| 70 | 16 | 50 | 140 | 280 | 490 | 1000 | 1200 | |||

| 80 | 10 | 43 | 110 | 230 | 410 | 960 | 980 | |||

| 100 | 10 | 43 | 120 | 260 | 450 | 950 | 1100 | |||

| Max. Output Torque | Nm | 1,2 | 3-100 | 3 Times of Normal Output Torque | ||||||

| Rated Input Speed | Rpm | 1,2 | 3-100 | 4000 | 4000 | 4000 | 3500 | 3000 | 2000 | 2000 |

| Max. Input Speed | Rpm | 1,2 | 3-100 | 6000 | 6000 | 6000 | 5500 | 4500 | 4500 | 4000 |

| Micro Backlash P0 | Arcmin | 1 | 3-10 | / | / | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 2 | 12-100 | / | / | / | ≤3 | ≤3 | ≤3 | ≤3 | ||

| Precision Backlash P1 | Arcmin | 1 | 3-10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 2 | 12-100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| Standard Backlash P2 | Arcmin | 1 | 3-10 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 |

| 2 | 12-100 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ||

| Torsional Rigidity | Nm/arcmin | 1,2 | 3-100 | 3 | 7 | 12 | 25 | 50 | 140 | 210 |

| Max. Radial Force | N | 1,2 | 3-100 | 780 | 1300 | 3200 | 6750 | 9400 | 14500 | 50000 |

| Max. Axial Force | N | 1,2 | 3-100 | 330 | 700 | 1580 | 3300 | 4700 | 7200 | 28000 |

| Service Life | Hr | 1,2 | 3-100 | 21000hrs | ||||||

| Efficiency | % | 1 | 3-10 | ≥97% | ||||||

| 2 | 12-100 | ≥94% | ||||||||

| Weight | Kg | 1 | 3-10 | 0.5 | 1.3 | 3.7 | 7.8 | 15 | 29 | 52 |

| 2 | 12-100 | 0.8 | 1.48 | 4.1 | 9.6 | 18.9 | 33 | 66 | ||

| Operating Temperature | ℃ | 1,2 | 3-100 | (-15℃~+90℃) | ||||||

| Lubrication | 1,2 | 3-100 | Synthetic Grease | |||||||

| Protection Class | 1,2 | 3-100 | IP65 | |||||||

| Mounting Position | 1,2 | 3-100 | Any Direction | |||||||

| Noise Level | dB(A) | 1,2 | 3-100 | ≤63 | ≤63 | ≤63 | ≤65 | ≤65 | ≤70 | ≤70 |

ພາບລວມຂອງ PAB Planetary Gear Reducer

ພາບລວມຂອງ PAB Planetary Gear Reducer