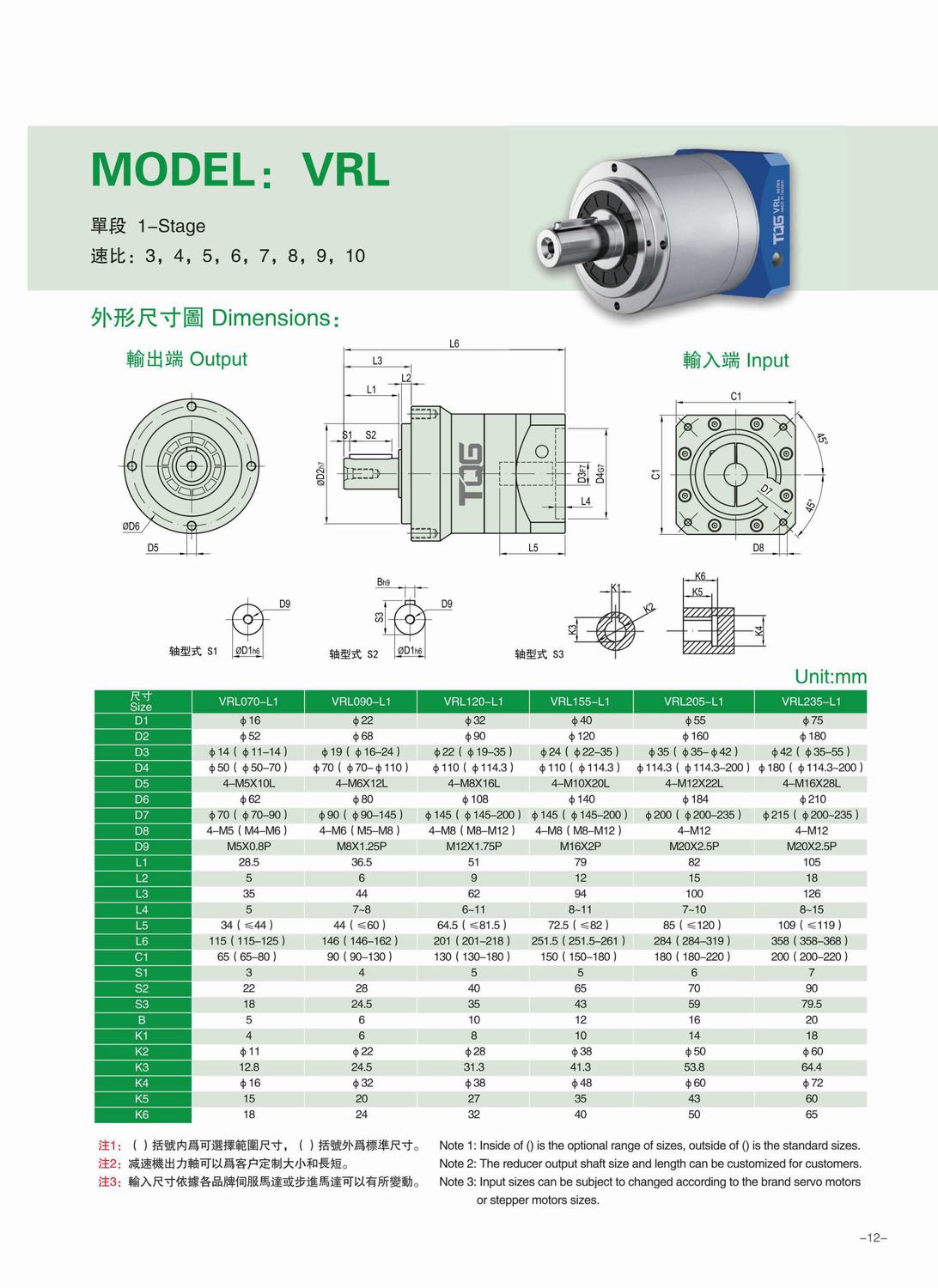

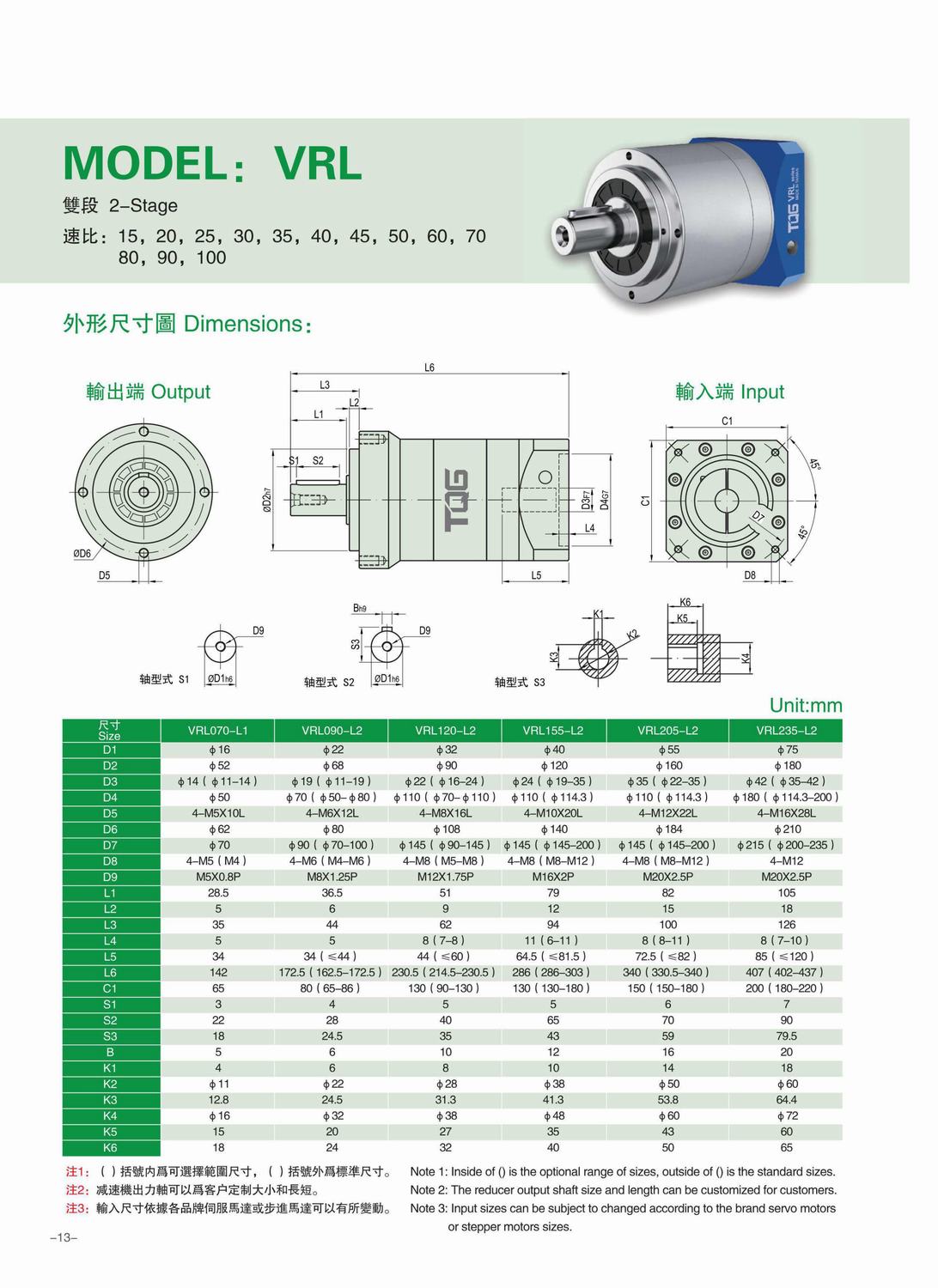

Overview of VRL Planetary Gearbox

Overview of VRL Planetary Gearbox

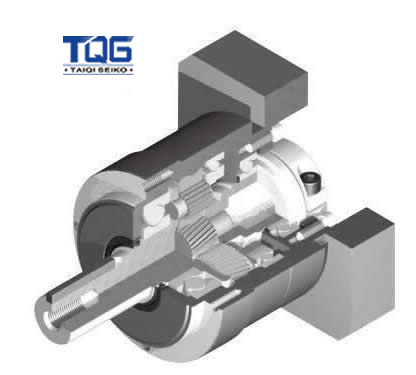

● High rigidity & torque

Rigid roller bearings are used to achieve high rigidity and high torque.

● High precision

Backlash smaller than 3arcmin, good choice for precision montion control

● Quiet operation

The use of helical gears to reduce vibration and noise.

● Adapter-bushing connection

Flexible connection method make it can be mounted to any brand of motor.

● No grease leakage

Use high viscosity anti separation oil to ensure no grease leakage.

● Maintenance-free

It can be mounted in any position and don’t have to replace the grease during the service life.

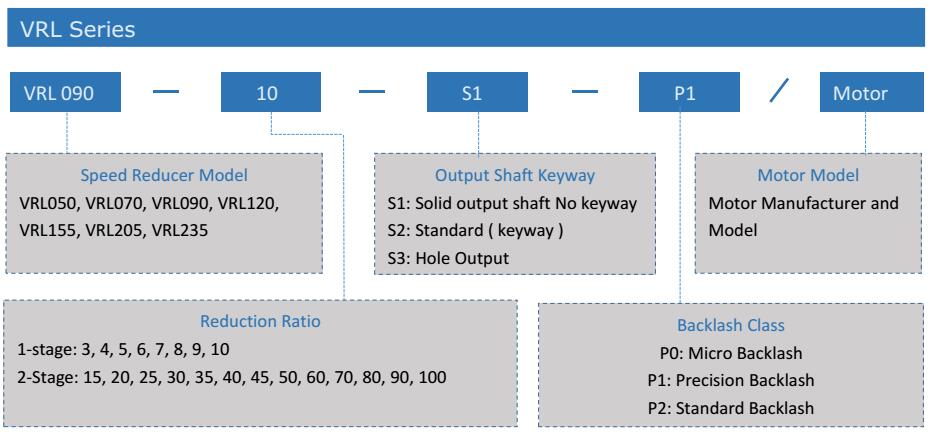

Indication of Model Numbers of VRL Speed Reducers

Description of VRL High Precision Planetary Gearboxes

VRL series speed reducer is a kind of inline planetary gearbox with good accuracy and high reliability. If high precision operation is required, our VRL is a good choice for you. Thread-in mounting method together with high level of precision and torque capacity make VRL speed reducer the best among similar products. Supplied with a coaxial shaft design, TQG VRL planetary gearbox is featured with 2~5 arcmin low balcklash class, can meet your various needs of accuracy.

Full dimensions of VRL series make it can directly replace the similar model of other brands on the market. High quality of machined planetary helical gears contribute to VRL reducer run more quietly and more effective. These series of VRL planetary reducers are widely used in injection molding machines, linear slides, pick and place automation, gantries, cutting and welding machines, etc. They are the perfect solutions for servo motor application.

TQG planetary gearheads are manufactured under the industry standard . They are easy to handle and available at very competitive price.

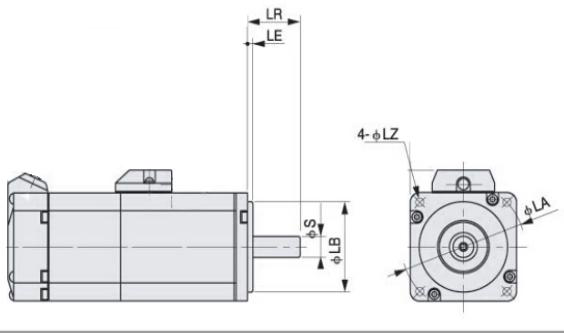

How to Select the Right Speed Reducer?

Step 1

What’s your motor brand and model? Or you can offer us the motor mounting dimension drawing like the following drawing with key sizes LR, LE, S, LB, LZ, LA

Step 2

What’s the ratio you need? Or pls tell us the nominated speed of your motor and the output speed of gearbox that you want.

*The speed ratio i=Motor Speed /output speed of gearbox

Step 3

What’s the output torque you need? Or pls tell us the power and the nominated speed of motor.

*The output torque (N.M)=9550x motor power(kw)/ motor speed (rpm)

*1 HP=0.75kw

Step 4

What’s your other requirement about the gearbox ? Such us flange, hole output, precision or backlash, noise value, shape of gearbox, inline or angle, etc. The more details requirement you offer us, the quicker we can select the suitable speed reducer gearbox for you.

Step 5

Download the catalogue from our website, check technical data, and get the right model.

| Model No. | Unit | Stage | Ratio | VRL050 | VRL070 | VRL090 | VRL120 | VRL155 | VRL205 | VRL235 |

| Rated Output Torque | Nm | 1 | 3 | 20 | 55 | 130 | 208 | 342 | 588 | 1140 |

| 4 | 19 | 50 | 140 | 290 | 542 | 1050 | 1700 | |||

| 5 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 6 | 20 | 55 | 150 | 310 | 600 | 1100 | 1900 | |||

| 7 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 8 | 17 | 45 | 120 | 260 | 500 | 1000 | 1600 | |||

| 9 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 10 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 2 | 15 | 20 | 55 | 130 | 208 | 342 | 588 | 1140 | ||

| 20 | 19 | 50 | 140 | 290 | 542 | 1050 | 1700 | |||

| 25 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 30 | 20 | 55 | 150 | 310 | 600 | 1100 | 1900 | |||

| 35 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 40 | 17 | 45 | 120 | 260 | 500 | 1000 | 1600 | |||

| 45 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 50 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 60 | 20 | 55 | 150 | 310 | 600 | 1100 | 1900 | |||

| 70 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 80 | 17 | 45 | 12 | 260 | 500 | 1000 | 1600 | |||

| 90 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 100 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| Max. Output Torque | Nm | 1,2 | 3-100 | 3 Times of Normal Output Torque | ||||||

| Rated Input Speed | Rpm | 1,2 | 3-100 | 5000 | 5000 | 4000 | 4000 | 3000 | 3000 | 2000 |

| Max. Input Speed | Rpm | 1,2 | 3-100 | 10000 | 10000 | 8000 | 8000 | 6000 | 6000 | 4000 |

| Micro Backlash P1 | Arcmin | 1 | 3-10 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

| 2 | 15-100 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| Precision Backlash P2 | Arcmin | 1 | 3-10 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 |

| 2 | 15-100 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ||

| Torsional Rigidity | Nm/arcmin | 1,2 | 3-100 | 3 | 7 | 14 | 25 | 50 | 145 | 225 |

| Max. Radial Force | N | 1,2 | 3-100 | 680 | 1260 | 2880 | 6000 | 8200 | 12800 | 27800 |

| Max. Axial Force | N | 1,2 | 3-100 | 330 | 625 | 1250 | 2400 | 3890 | 6100 | 15000 |

| Service Life | Hr | 1,2 | 3-100 | 20000hrs | ||||||

| Efficiency | % | 1 | 3-10 | ≥97% | ||||||

| 2 | 15-100 | ≥94% | ||||||||

| Weight | Kg | 1 | 3-10 | 0.5 | 1.2 | 3.5 | 7.8 | 14.5 | 30 | 50 |

| 2 | 15-100 | 0.8 | 1.4 | 4.1 | 9 | 17.5 | 33 | 63 | ||

| Operating Temperature | ℃ | 1,2 | 3-100 | (-15℃~+90℃) | ||||||

| Lubrication | 1,2 | 3-100 | Synthetic Grease | |||||||

| Protection Class | 1,2 | 3-100 | IP65 | |||||||

| Mounting Position | 1,2 | 3-100 | Any Direction | |||||||

| Noise Level | dB(A) | 1,2 | 3-100 | ≤56 | ≤58 | ≤60 | ≤63 | ≤65 | ≤67 | ≤70 |

Overview of VRL Planetary Gearbox

Overview of VRL Planetary Gearbox