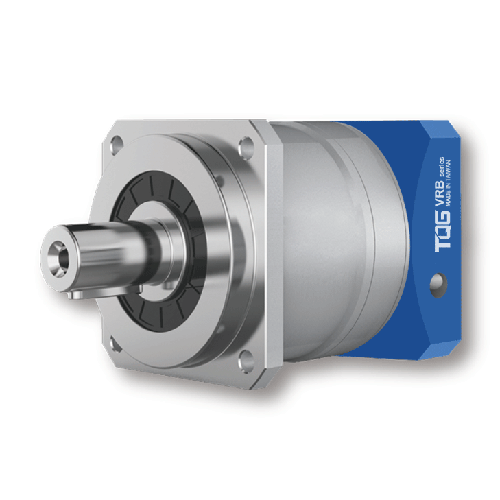

Overview of VRB Speed Reducer

- The integral structure of the planetary wall frame and the output shaft ensures the maximum torsion rigidity and stability.

- Lowest backlash of 0-2 arcmin thank to high precision gear machining.

- Square flange output method to achieve the quick connection with any motor.

- High efficiency of 95% due to high meshing degree of high rigidity gears

- Maintenance free due to lifetime synthetic grease lubrication stem.

Penerangan tentang VRB High Precision Planetary Gearboxes:

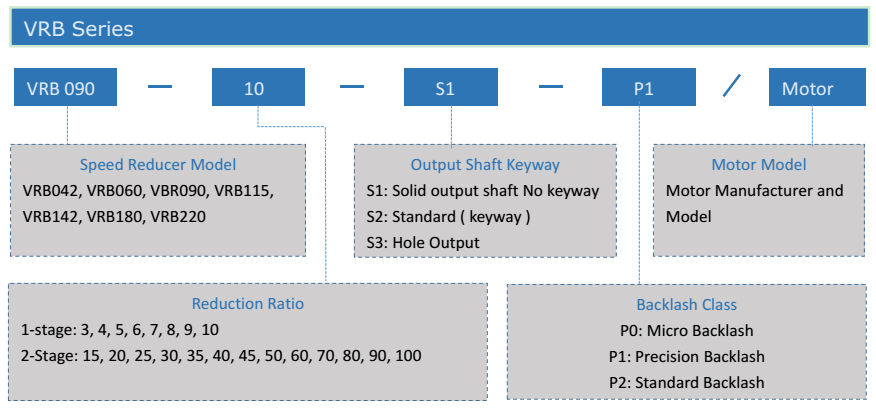

Taiqi Seiko is focus on developing the precision-gear technology to meet the increasing needs of customers in industrial automation fields. Taiqi Seiko VRB series are the works of our research and development. We offer VRB series gearboxes with the most comprehensive choice of frame sizes and reduction ratios and can be suitable for different configurations. Industrial standard mounting dimensions allow Taiqi VRB to be adaptable to different equipment designs, saving our customers’ time and money. VRB series high precision planetary gearboxes are the equivalent products of PAB series. Compared with PAB square shape frame, VRB series planetary gearboxes are designed with a round shape. They are all inline gearboxes. PAB precision reducers has border precision ranges for select. VRB planetary gearboxes only have two optional backlash for your choice: Micro precision backlash (P0) and precision backlash (P1) , without standard precision backlash (P2). On the aspect of sizes and torque values, there is a slight difference. VRB planetary gearboxes also offer a wide sizes for selection, which can meet customer different application needs. For the more details, please check our related catalogue page. Taiqi VRB Series planetary gearboxes are applicable for servo motors and stepper motors of brands like Panasonic, Fanuc, SIEMENS, Matsushita, Mitsubishi, Lenz, Yaskawa, etc.

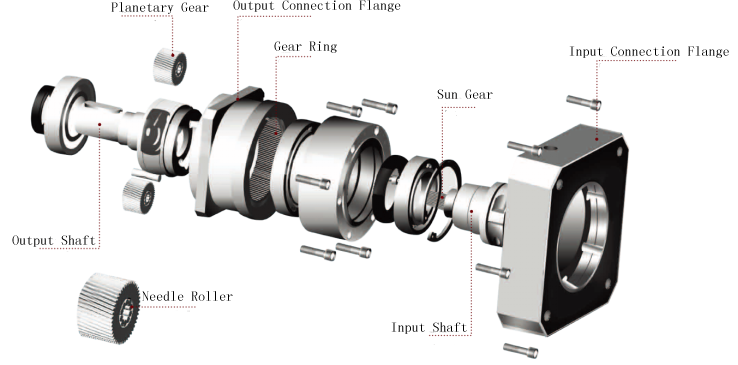

Graphic Analysis of VRB High Precision Planetary Gearboxes

Application of VRB High Precision Planetary Reducers:

Taqi Seiko VRB High Precision Planetary reducers are the perfect solution for servomotor applications, which are widely applied in polishing machine, paper equipment, solar energy equipment, CNC cutting machine, glass equipment, pipe bending machine, automobile equipment, reciprocating machine, engraving machine, woodworking machinery, aluminum curtain door and window equipment, injection molding machine, circuit board equipment, packaging equipment, experimental equipment, coating machine, precision testing instrument, university scientific research Institute, etc.

Taiqi Seiko Superior Manufacturing Processes of VRB Planetary Gearbox:

All the components are controlled by TQG strict quality control system. The planetary gears and sun gear are all helical gears, carburized and quenched to 58-62HRC, and will be proceeded the precision grinding and technical corrected to achieve perfect transmission effect. The planetary gear is supported by two ends of the needle rollers, which has enhanced the torsional stiffness. The protection level of TQG planetary gearbox is up to the international standard IP65 (full dustproof and waterproof).

Patent of PAB series Planetary Gear Reducers:

TQG PAB series planetary gearboxes are featured with two multi-national patent of lubricating construction, which is applied in the internal spiral gear structure to ensure the highest output efficient .

Patent 1: Reduce the axial thrust of the planetary gear running.

Patent 2: Increase the lubrication, reduce the frictional resistance and noise.

| Model No. | Unit | Stage | Nisbah | VRB042 | VRB060 | VRB090 | VRB115 | VRB142 | VRB180 | VRB220 |

| Rated Output Torque | Nm | 1 | 3 | 20 | 55 | 130 | 208 | 342 | 588 | 1140 |

| 4 | 19 | 50 | 140 | 290 | 542 | 1050 | 1700 | |||

| 5 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 6 | 20 | 55 | 150 | 310 | 600 | 1100 | 1900 | |||

| 7 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 8 | 17 | 45 | 120 | 260 | 500 | 1000 | 1600 | |||

| 9 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 10 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 2 | 15 | 20 | 55 | 130 | 208 | 342 | 588 | 1140 | ||

| 20 | 19 | 50 | 140 | 290 | 542 | 1050 | 1700 | |||

| 25 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 30 | 20 | 55 | 150 | 310 | 600 | 1100 | 1900 | |||

| 35 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 40 | 17 | 45 | 120 | 260 | 500 | 1000 | 1600 | |||

| 45 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 50 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 60 | 20 | 55 | 150 | 310 | 600 | 1100 | 1900 | |||

| 70 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 80 | 17 | 45 | 120 | 260 | 500 | 1000 | 1600 | |||

| 90 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 100 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| Max. Output Torque | Nm | 1,2 | 3-100 | 3 Times of Normal Output Torque | ||||||

| Rated Input Speed | Rpm | 1,2 | 3-100 | 5000 | 5000 | 4000 | 4000 | 3000 | 3000 | 2000 |

| Max. Input Speed | Rpm | 1,2 | 3-100 | 10000 | 10000 | 8000 | 8000 | 6000 | 6000 | 4000 |

| Micro Backlash P0 | Arcmin | 1 | 3-10 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

| 2 | 12-100 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

| Precision Backlash P1 | Arcmin | 1 | 3-10 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 |

| 2 | 12-100 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ||

| Torsional Rigidity | Nm / arcmin | 1,2 | 3-100 | 3 | 7 | 14 | 25 | 50 | 145 | 225 |

| Max. Radial Force | N | 1,2 | 3-100 | 780 | 1530 | 3250 | 6700 | 9400 | 14500 | 50000 |

| Max. Axial Force | N | 1,2 | 3-100 | 350 | 630 | 1300 | 3000 | 4000 | 6200 | 35000 |

| Service Life | Hr | 1,2 | 3-100 | 20000hrs | ||||||

| Efficiency | % | 1 | 3-10 | ≥97% | ||||||

| 2 | 15-100 | ≥94% | ||||||||

| Berat badan | Kg | 1 | 3-10 | 0.5 | 1.3 | 3.3 | 7.8 | 15 | 28 | 52 |

| 2 | 15-100 | 0.8 | 1.48 | 3.9 | 9.6 | 18.9 | 33 | 66 | ||

| Operating Temp. | ℃ | 1,2 | 3-100 | (-15℃~+90℃) | ||||||

| Lubrication | 1,2 | 3-100 | Synthetic Grease | |||||||

| Protection Class | 1,2 | 3-100 | IP65 | |||||||

| Mounting Position | 1,2 | 3-100 | Any Direction | |||||||

| Noise Level | dB(A) | 1,2 | 3-100 | ≤56 | ≤58 | ≤60 | ≤63 | ≤65 | ≤67 | ≤70 |