Overview of PFR Speed Reducer

Overview of PFR Speed Reducer

● Square flange output design ensure fast connection with any motor

● High rigidity & torque due to the use of needle roller bearing

● Spiral bevel gears are adopted to ensure the lowest backlash

● Space-saving design

Motors can be mounted at a 90 degree to save the space

● No leakage of grease

High viscosity and non-separated grease is used to avoid the leakage.

● Square flange output design ensure fast connection with any motor

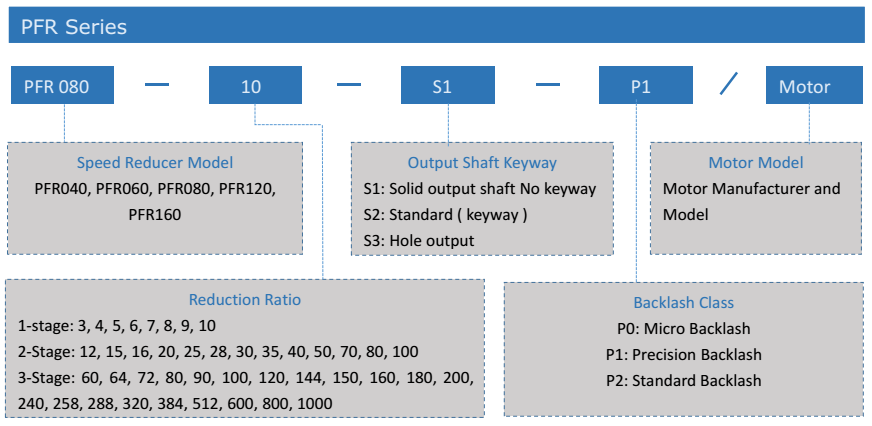

Indication of Model Numbers of PFR Speed Reducers

Descrição de PFR Planetary Speed Reducer

PFR series right angle gearbox is designed for solve the problems of space. The compact structure of PFR speed reducer provides customer with a good solution when installation space or clearance are limited. High precision and solid construction make PFR speed reducer more valuable than other similar gearbox. Two ends of needle roller bearings with high precision on the shaft backup the planetary gears to improve the torsional stiffness of speed reducer. Meanwhile, this planetary gearbox is also an economy pecision gear reducer, providing an excellent choice for customers who has limited budget. In addition, flanged output design make it easier to connect with the equipment.

Application of PFR Precision Planetary Gearbox

Precision planetary reducer is widely used in various fields: environmental protection equipment, precision instruments, flame cutting, CNC machine tools, tool machinery, automation industry, printing machinery, textile printing and dyeing, pharmaceutical leather, environmental protection equipment, coal equipment, cement equipment, beer drink, mining machinery, wire rope transmission life test machine, glass equipment, winding machine, food packaging, welding equipment, CNC machine tools, laser cutting, industrial robot measuring equipment, rubber plastics, petrochemical, lifting transportation and other light and heavy industry, mechanical transmission and precision control field.

Taiqi Seiko Superior Manufacturing Processes of PFR Planetary Gearbox:

Todos os componentes são controlados pelo sistema de controle de qualidade rigoroso TQG. As engrenagens planetárias e a engrenagem solar são todas engrenagens helicoidais, cementadas e temperadas a 58-62HRC, e proceder-se-á à retificação de precisão e corrigida tecnicamente para obter um efeito de transmissão perfeito. A engrenagem planetária é suportada por duas extremidades dos rolos de agulhas, o que aumentou a rigidez de torção. O nível de proteção da caixa de engrenagens planetárias TQG está de acordo com o padrão internacional IP65 (à prova de poeira e à prova d'água).

Patent of PFR series Planetary Gear Reducers:

TQG PFR series planetary gearboxes are featured with two multi-national patent of lubricating construction, which is applied in the internal spiral gear structure to ensure the highest output efficient .

Patente 1: Reduza o impulso axial da engrenagem planetária em funcionamento.

Patente 2: Aumentar a lubrificação, reduzir a resistência ao atrito e o ruído.

| Modelo não. | Unidade | Palco | Ratio | PER040 | PER060 | PER080 | PER120 | PER160 |

| Torque de saída avaliado | Nm | 1 | 3 | 17 | 28 | 112 | 165 | 423 |

| 4 | 15 | 38 | 110 | 146 | 364 | |||

| 5 | 14 | 40 | 108 | 160 | 423 | |||

| 7 | 13 | 35 | 105 | 149 | 358 | |||

| 10 | 12 | 25 | 100 | 141 | 293 | |||

| 2 | 15 | 17 | 28 | 112 | 165 | 423 | ||

| 20 | 15 | 38 | 110 | 146 | 364 | |||

| 25 | 14 | 40 | 108 | 160 | 423 | |||

| 30 | 13 | 28 | 112 | 165 | 423 | |||

| 35 | 13 | 35 | 105 | 149 | 358 | |||

| 40 | 12 | 38 | 110 | 146 | 364 | |||

| 50 | 14 | 40 | 108 | 160 | 423 | |||

| 70 | 13 | 35 | 105 | 149 | 358 | |||

| 100 | 12 | 25 | 100 | 141 | 293 | |||

| Max. Torque de Saída | Nm | 1,2 | 3-100 | 3 vezes de torque de saída normal | ||||

| Velocidade de entrada nominal | Rpm | 1,2 | 3-100 | 3000 | 3000 | 3000 | 3000 | 2500 |

| Max. Velocidade de entrada | Rpm | 1,2 | 3-100 | 5000 | 5000 | 5000 | 5000 | 3600 |

| Folga de Precisão P1 | Arcmin | 1 | 3-10 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 |

| 2 | 12-100 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ||

| Backlash padrão P2 | Arcmin | 1 | 3-10 | ≤11 | ≤11 | ≤11 | ≤11 | ≤11 |

| 2 | 12-100 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ||

| Rigidez torcional | Nm / arcmin | 1,2 | 3-100 | 3 | 6 | 12 | 22 | 50 |

| Max. Força Radial | N | 1,2 | 3-100 | 320 | 460 | 1300 | 3200 | 6520 |

| Max. Força axial | N | 1,2 | 3-100 | 160 | 230 | 660 | 1600 | 3260 |

| Vida de serviço | Hora | 1,2 | 3-100 | 20000hrs | ||||

| Eficiência | % | 1 | 3-10 | ≥97% | ||||

| 2 | 15-100 | ≥ 94% | ||||||

| Peso | Kg | 1 | 3-10 | 0.73 | 0.99 | 2.1 | 4.98 | 18.2 |

| 2 | 15-100 | 1.05 | 1.46 | 3.2 | 6.92 | 24.9 | ||

| Temperatura de operação | ℃ | 1,2 | 3-100 | (-25℃~+90℃) | ||||

| Lubrificação | 1,2 | 3-100 | Graxa Sintética | |||||

| Aula de proteção | 1,2 | 3-100 | IP65 | |||||

| Posição de montagem | 1,2 | 3-100 | Qualquer direção | |||||

| Nível de ruído | dB (A) | 1,2 | 3-100 | ≤62 | ≤63 | ≤65 | ≤67 | ≤ 68 |

Moment of Inertia