Visão geral de VRS Redutor planetário de engrenagens

Visão geral de VRS Redutor planetário de engrenagens

- Coaxial shaft design

- Standard mounting dimensions

- Broad frame sizes available

- High rigidity with large output torque

- High accuracy & Low backlash (1~3 arcmin)

- For servo motor and stepper motor

- Excelent performance and stablity

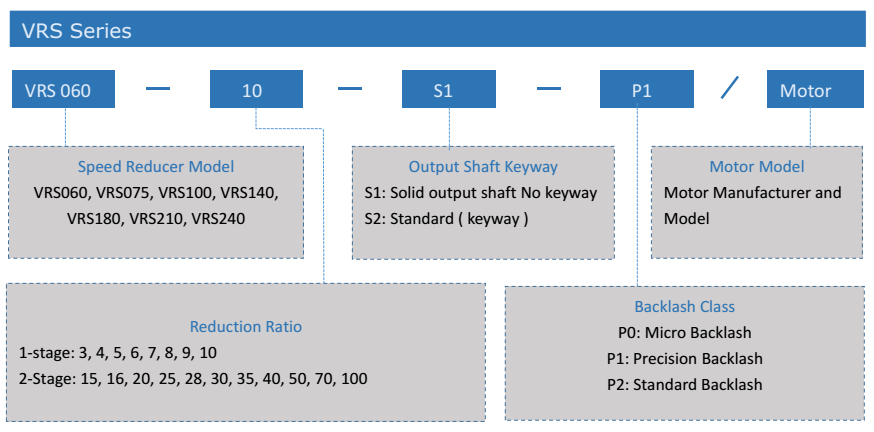

Indication of Model Numbers of VRS Speed Reducers

Descrição de VRS High Precision Servo Caixas de engrenagens

TQG high quality PAF series are inline servo speed reducer with a sturdy design and specially matched with stepper motor and servo motor, brands such like Panasonic, Yaskawa, Mitsubishi, Omron, Teco, Leadshine, etc. There are two optional backlash of VRS series planetary gearboxes: Micro precision backlash P0 (1~3 arcmin) and precision backlash P1 (3~5 arcmin). This planetary speed reducer has superior load capabilities, and is an ideal selection for higher speed and continuous duty applications. The tapered roller bearings at the output of the reducer gearbox allow the VRS reducer to handle larger radial and thrust loads. This internal design provides an extremely smooth and quiet running.

Application of VRS Planetary Reducers

As a recommended precision planetary servo gearbox, it is a perfect solution for extreme duty-operation for servo application, including gantries, printing equipment, packaging machinery, linear slides, loader robot, injection molding machines, food processing machinery, turret head, auto packing sealing machine, dispenser robot, or any other servo application that require high precision and large radial and thrust loading capacity.

| Modelo não. | Unidade | Palco | Ratio | VRS060 | VRS075 | VRS100 | VRS140 | VRS180 | VRS210 | VRS240 |

| Torque de saída avaliado | Nm | 1 | 3 | 55 | 130 | 208 | 342 | 586 | 1140 | 1500 |

| 4 | 50 | 140 | 290 | 542 | 1050 | 1700 | 2500 | |||

| 5 | 60 | 160 | 330 | 650 | 1200 | 2000 | 2500 | |||

| 6 | 55 | 150 | 310 | 600 | 1100 | 1900 | 2260 | |||

| 7 | 50 | 140 | 300 | 550 | 1100 | 1800 | 2300 | |||

| 8 | 45 | 120 | 260 | 500 | 1000 | 1600 | 2100 | |||

| 9 | 40 | 100 | 230 | 450 | 900 | 1500 | 1800 | |||

| 10 | 40 | 100 | 230 | 450 | 900 | 1500 | 1800 | |||

| 2 | 15 | 55 | 130 | 208 | 342 | 586 | 1140 | 2300 | ||

| 16 | 55 | 130 | 208 | 342 | 586 | 1140 | 2300 | |||

| 20 | 50 | 140 | 290 | 542 | 1050 | 1700 | 2500 | |||

| 25 | 60 | 160 | 330 | 650 | 1200 | 2000 | 2500 | |||

| 28 | 60 | 160 | 330 | 650 | 1200 | 2000 | 2500 | |||

| 30 | 55 | 150 | 310 | 600 | 1100 | 1900 | 2300 | |||

| 35 | 50 | 140 | 300 | 550 | 1100 | 1800 | 2200 | |||

| 40 | 45 | 120 | 260 | 500 | 1000 | 1600 | 2350 | |||

| 50 | 60 | 160 | 330 | 650 | 1200 | 2000 | 2200 | |||

| 70 | 50 | 140 | 300 | 550 | 1100 | 1800 | 2200 | |||

| 100 | 40 | 100 | 230 | 450 | 900 | 1500 | 1800 | |||

| Max. Torque de Saída | Nm | 1,2 | 3-100 | 3 vezes de torque de saída normal | ||||||

| Velocidade de entrada nominal | Rpm | 1,2 | 3-100 | 5000 | 4000 | 4000 | 3000 | 3000 | 2000 | 1000 |

| Max. Velocidade de entrada | Rpm | 1,2 | 3-100 | 10000 | 8000 | 8000 | 6000 | 6000 | 4000 | 2500 |

| Micro folga P0 | Arcmin | 1 | 3-10 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 2 | 12-100 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ||

| Folga de Precisão P1 | Arcmin | 1 | 3-10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 2 | 15-100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| Rigidez torcional | Nm / arcmin | 1,2 | 3-100 | 7 | 14 | 25 | 50 | 145 | 225 | 260 |

| Max. Força Radial | N | 1,2 | 3-100 | 2750 | 4100 | 6400 | 9880 | 15000 | 20000 | 27500 |

| Max. Força axial | N | 1,2 | 3-100 | 2350 | 3200 | 5360 | 9690 | 14200 | 28000 | 30000 |

| Vida de serviço | Hora | 1,2 | 3-100 | 20000hrs | ||||||

| Eficiência | % | 1 | 3-10 | ≥96% | ||||||

| 2 | 15-100 | ≥93% | ||||||||

| Peso | Kg | 1 | 3-10 | 1.8 | 3.8 | 7.2 | 16.8 | 32 | 49 | 65 |

| 2 | 15-100 | 2.1 | 4.1 | 8.1 | 17.5 | 35 | 53 | 70 | ||

| Temperatura de operação | ℃ | 1,2 | 3-100 | (-15 ℃ ~ + 90 ℃) | ||||||

| Lubrificação | 1,2 | 3-100 | Graxa Sintética | |||||||

| Aula de proteção | 1,2 | 3-100 | IP65 | |||||||

| Posição de montagem | 1,2 | 3-100 | Qualquer direção | |||||||

| Nível de ruído | dB (A) | 1,2 | 3-100 | ≤62 | ≤62 | ≤65 | ≤ 68 | ≤ 68 | ≤70 | ≤70 |

Visão geral de VRS Redutor planetário de engrenagens

Visão geral de VRS Redutor planetário de engrenagens