Prezentare generală a HK Series Worm Screw Jack

Prezentare generală a HK Series Worm Screw Jack

- It is suitable for low speed and low frequency operation.

- The screw Jack features of a self-locking functionto realize continuous loading

- With a compact structure, small volume and light weight.

- With wide power source, can be driven by motor or other power or manually.

- The screw lift can be used separately or in combination.

- More advantages such as low noise, easy to install and long service life.

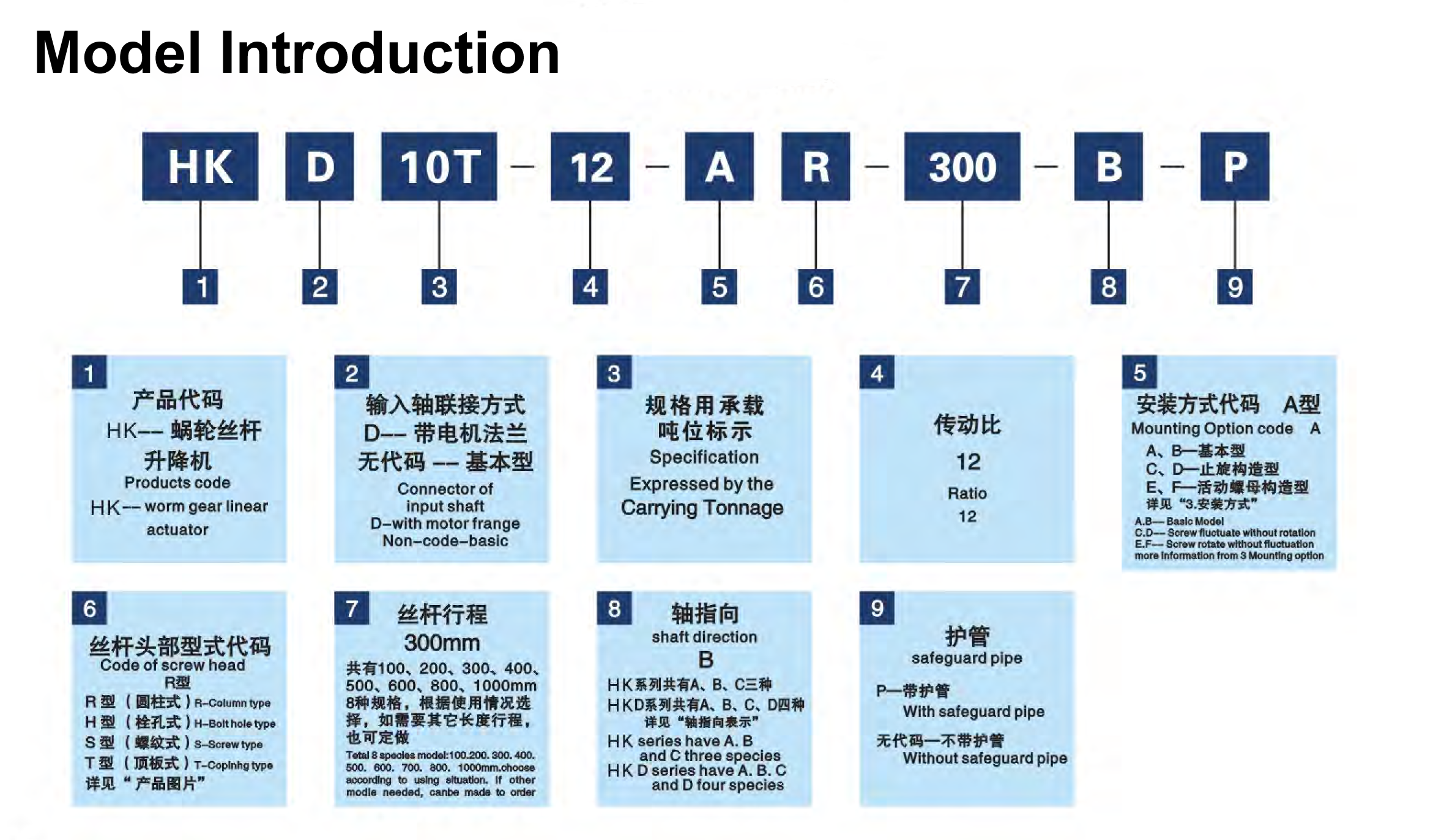

Description of HK Series Worm Screw Lift

HK Worm Gear Screw lift also known as screw Jack, is suitable for low speed and heavy load applications. TQG worm gear screw jack features of intermittent precisely positioning and self-locking functions, and it does not need brake mechanism or other locking systems. Besides, various kinds of installation types are available due to it has different types of screw lift structures.

With a wide range of power sources, the HK worm gear screw lift can be driven directly by motor or other power, or by hand. It adopts a advanced technology to realize high efficiency and high load capacity.

Screw Jacks are mainly used for raising and lowering maintenance platforms, opening and closing air dampers, oven doors, sluice gates, adjusting tooling machine beds, cable tension and workplace tables.

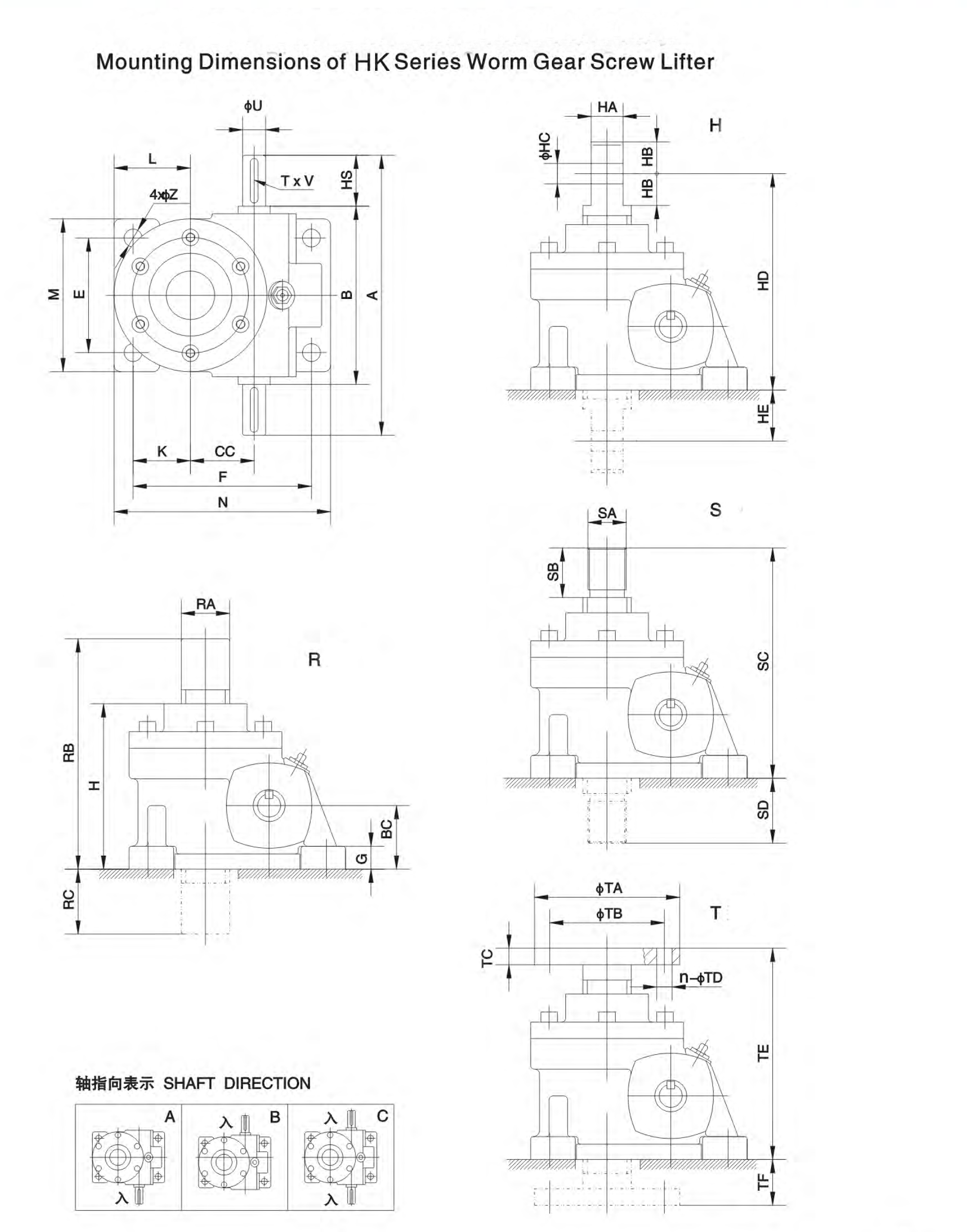

Mounting options

- Basic: The most common mounted lift is to force the screw rod to move up and down through worm gear.

- Stop rotating: It is suitable for operation without top connection and other applications when non-rotation can’t be achieved.

- Movable nut: The movable nut screw lift is an ideal choice when users want to lengthen the stroke in a limited space. When the stroke is longer, the end of the shaft must be supported in order to realize high transmission efficiency.

Prezentare generală a HK Series Worm Screw Jack

Prezentare generală a HK Series Worm Screw Jack