Overview of Foot Mounted Orthogonal Shaft Small Gear Motor

Overview of Foot Mounted Orthogonal Shaft Small Gear Motor

- Nizka temperatura narašča

- Wide range ratio

- High rigity & strength

- High operating efficiency

- Superior cost performance

- Brez vzdrževanja

Descriptions of Foot Mounted Orthogonal Shaft Small Gear Motor

The Taiqi foot mounted orthogonal shaft small gear motor adopts the hypoid gearing design, which has the characteristics of low noise of helical gear and high efficiency of bevel gear in performance. The hypoid gear motor of TQG are made of special steels through advanced processing techniques and carburizing hardening processes, so that the rigity and service life is higher than those of worm gear reducers. Compared with the worm gear, the sliding friction of the hypoid gear is smaller, and the transmission efficiency is higher than that of the worm gear which is up to 98%. What’s more, it is small in volume and saves the installation space.

Materials of Foot Mounted Orthogonal Shaft Small Gear Motor

- The box body of Taiqi Seiko is made of high-quality alloy materialand the surface paint of the reducer is sprayed at high temperature after high pressure atomization which greatly improves the rigity and anti-corrrosion.

- The coil is made of 100% pure copper wire coil with high insulation grade and high temperature resistance.

- The core of foot mounted orthogonal shaft small gear motor adopts high quality pure copper core, low temperature, low noise, high torque and long service life.

- The foot mounted orthogonal shaft samall gear motor adopts imported gear with precision rolling and grinding and it features high precision and high rigity.

Features of Foot Mounted Orthogonal Shaft Small Gear Motor

- Goodsealing performance

With the using of synthetic lubricating grease of the TQG gear motor, it is good in sealing and maintainence-free and no leakage.

- High heat dissipationefficiency

The Taiqi foot mounted orthogonal shaft small gear motor adopts aluminum alloy box design and compared with the cast iron box, it has a better heat dissipation.

- Quiet operation

The gear meshing of the spiral bevel gear is usually about 2 teeth, and the hypoid gear’s is more than 2.5 teeth which contributes to the lower noise in operating.

- Easy installation

Due to adopting lubricating grease, the installation diirection is not limited, and various installation methods such as foot, flange, shaft installation could be choosed.

Aplikacije

The foot mounted orthogonal axis small hypoid gear motors of TQG are widely used in food machinery, textile machinery, packaging machinery, environmental protection equipment, conveying equipment and other machinery automation fields.

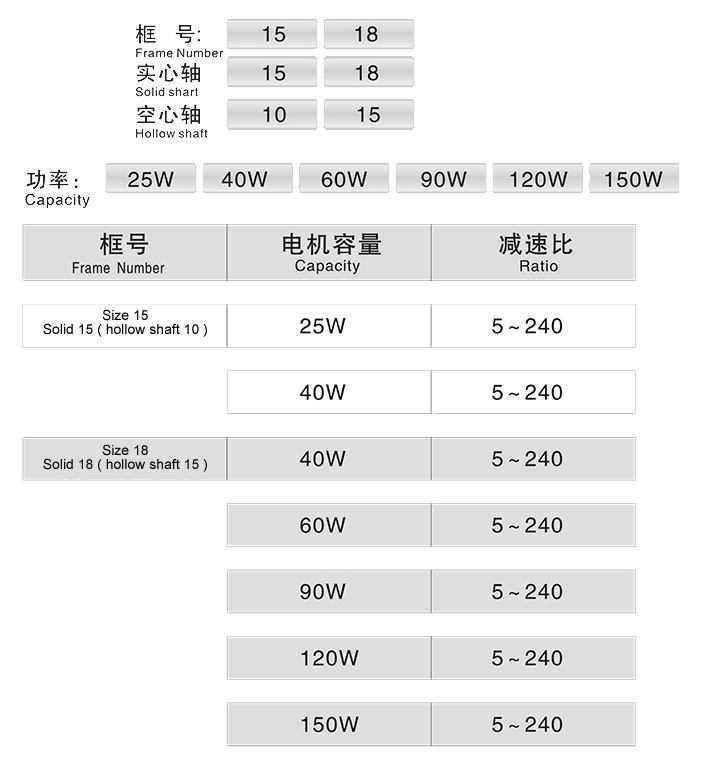

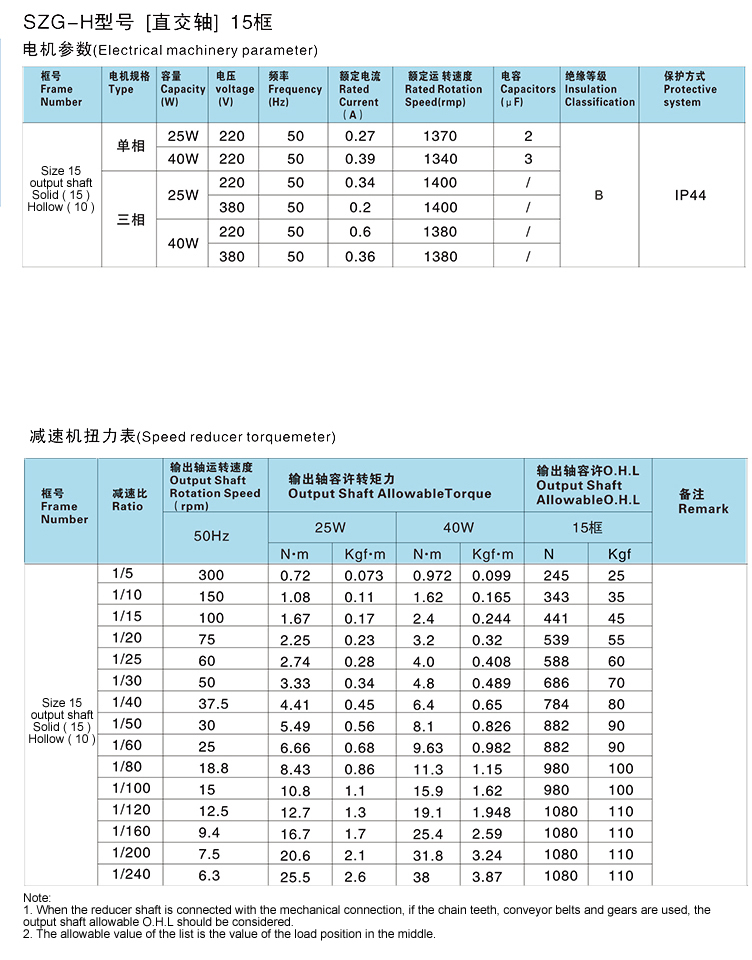

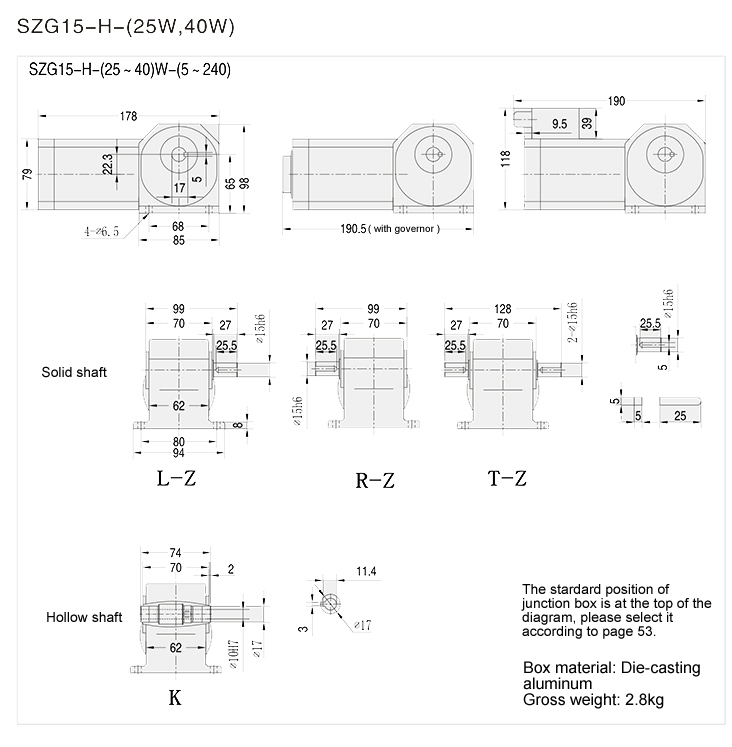

Navedba vzorčnih številk Foot Mounted Orthogonal Shaft Small Gear Motor

Overview of Foot Mounted Orthogonal Shaft Small Gear Motor

Overview of Foot Mounted Orthogonal Shaft Small Gear Motor