Overview of Servo Electric Cylinder

Overview of Servo Electric Cylinder

- TQG Servo Electric Cylinder can work in harsh environments with the features of waterproof, explosion-proof, anti-salt spray.

- The different output types, different speeds, and different stroke of electric cylinder be produced according to customer’s needs.

- It adopts high precision screw to realize high positioning precision, and the stroke and speed is adjustable.

- Low noise, energy saving, and long service life.

- Small size, light weight, and easy to install.

Descriptions of Servo Electric Cylinder

TQG Servo Electric Cylinder was driven by the power of servo motor, the screw inside is able to move forward and backward to create force. Compared to traditional hydraulic and pneumatic cylinder, Taiqi servo electric cylinder features of high precision, adjustable speed, controllable force, and long service life, and it also can replace the traditional hydraulic and pneumatic cylinder and operate under stricter environment.

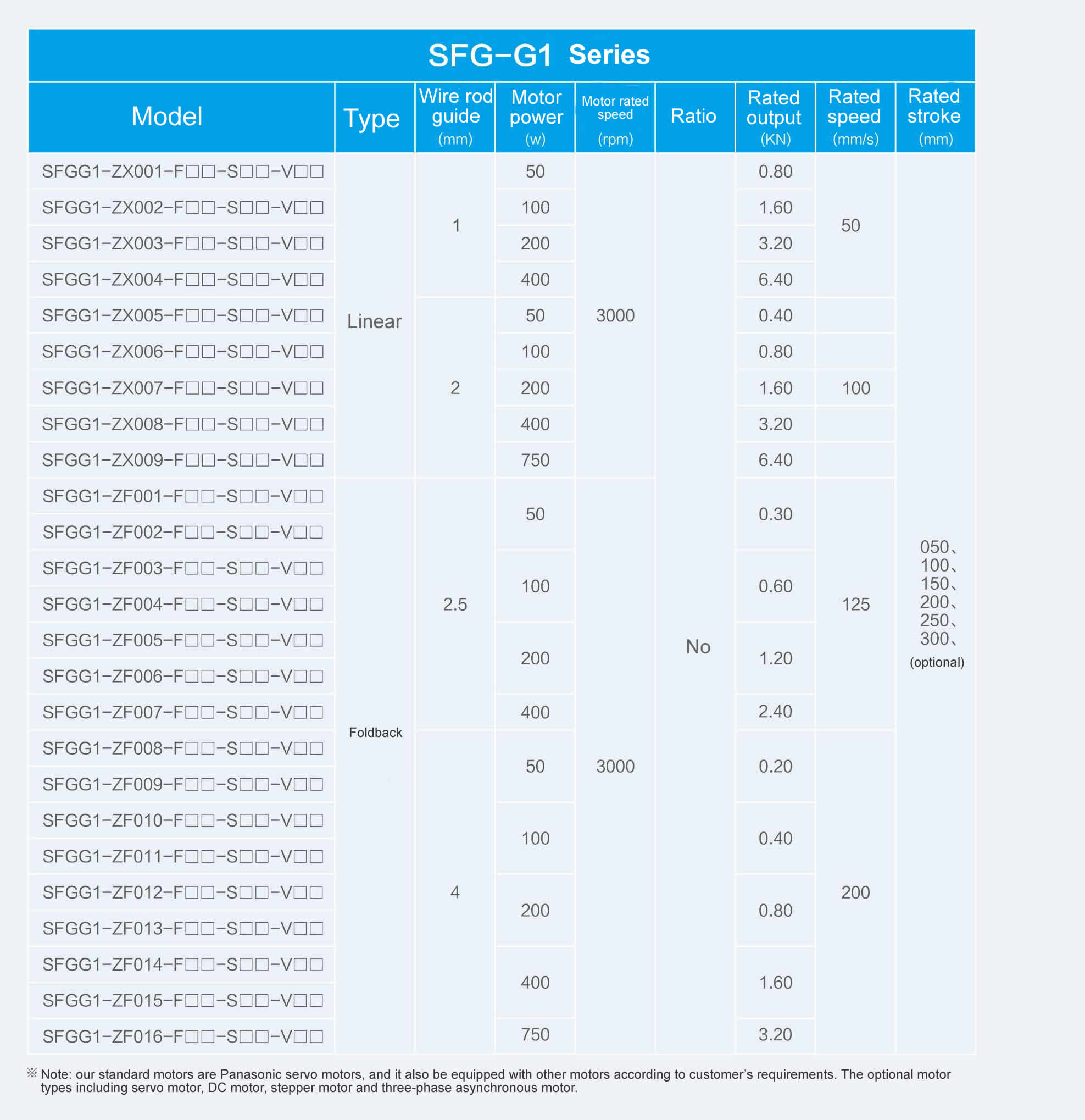

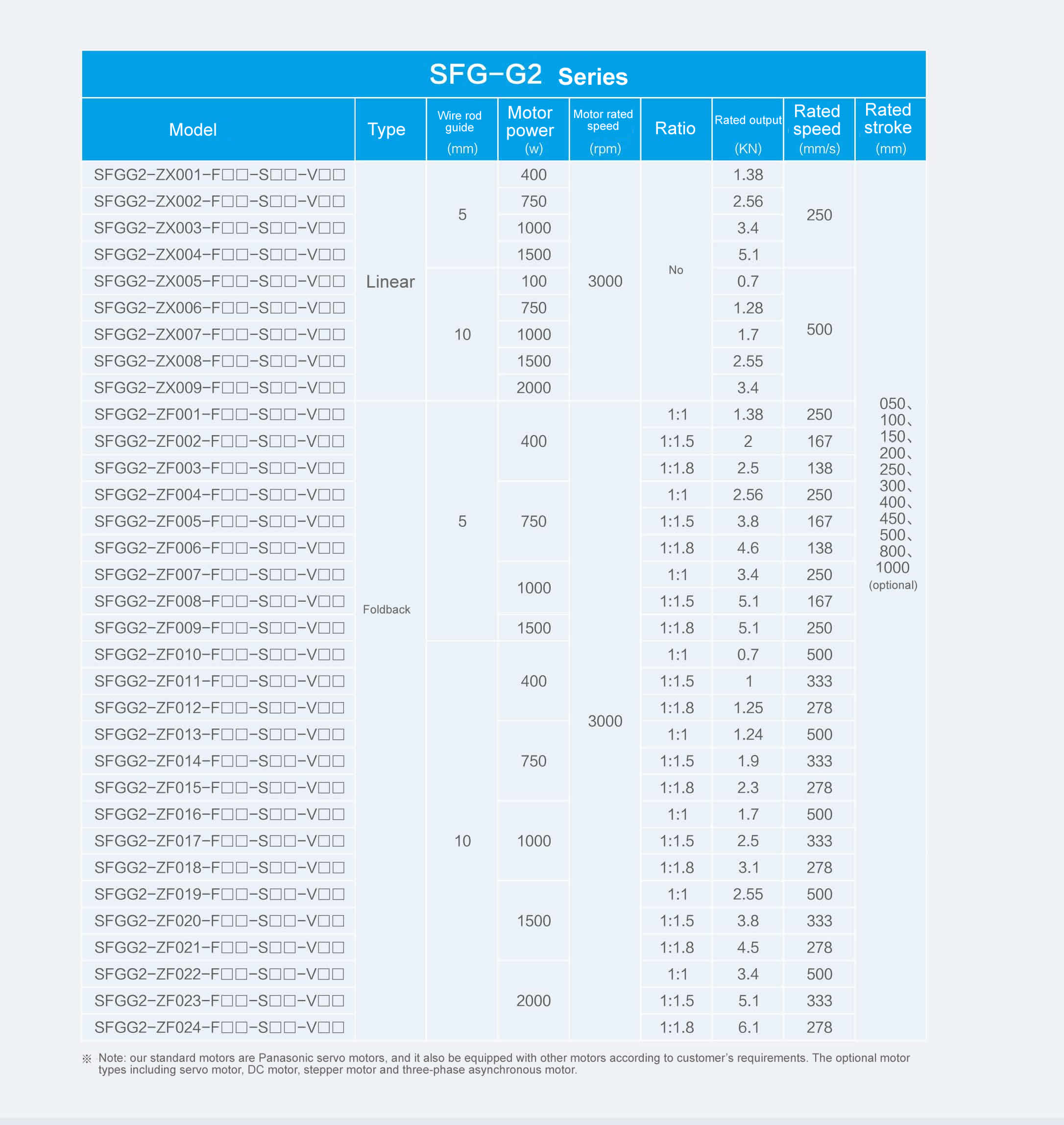

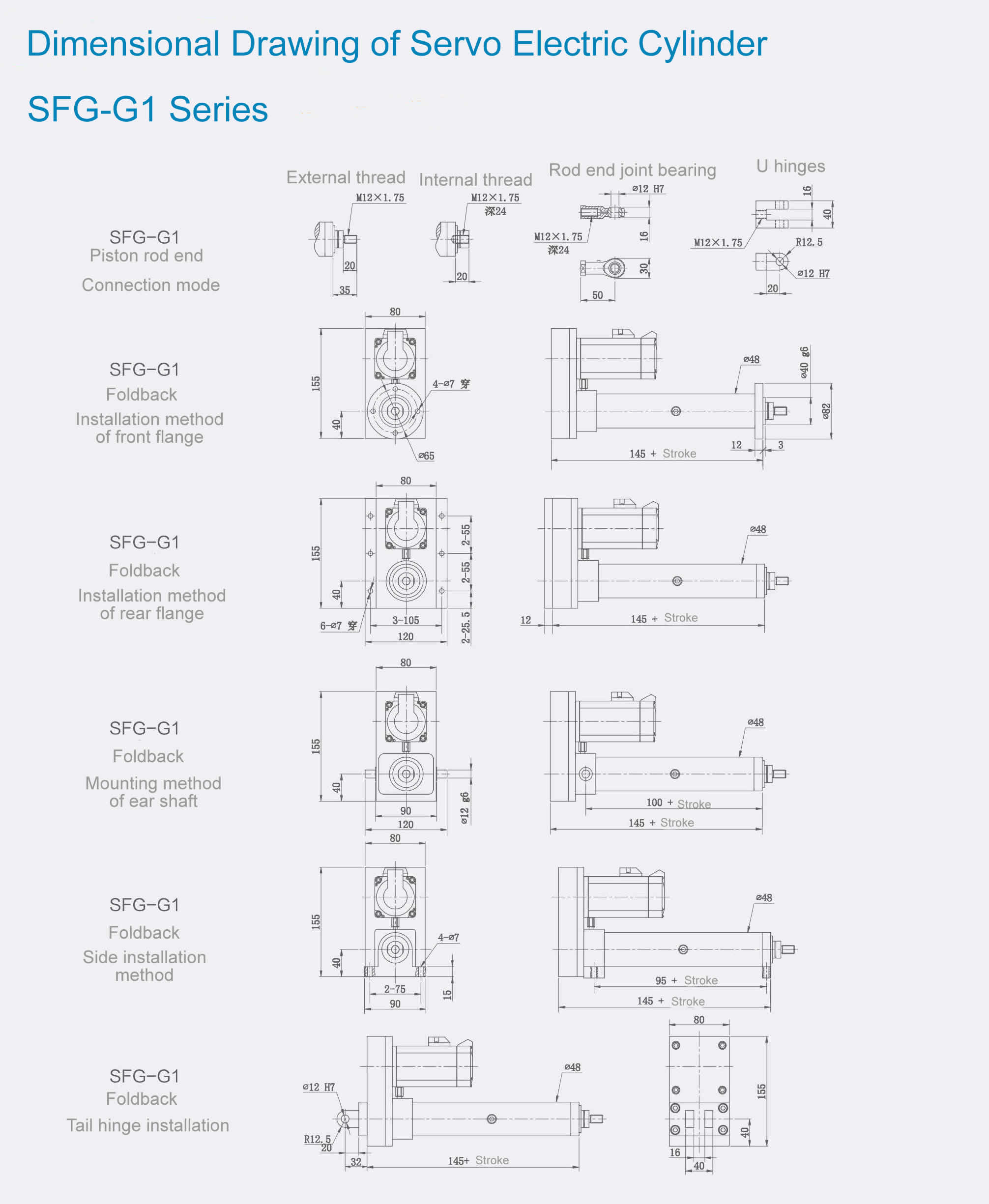

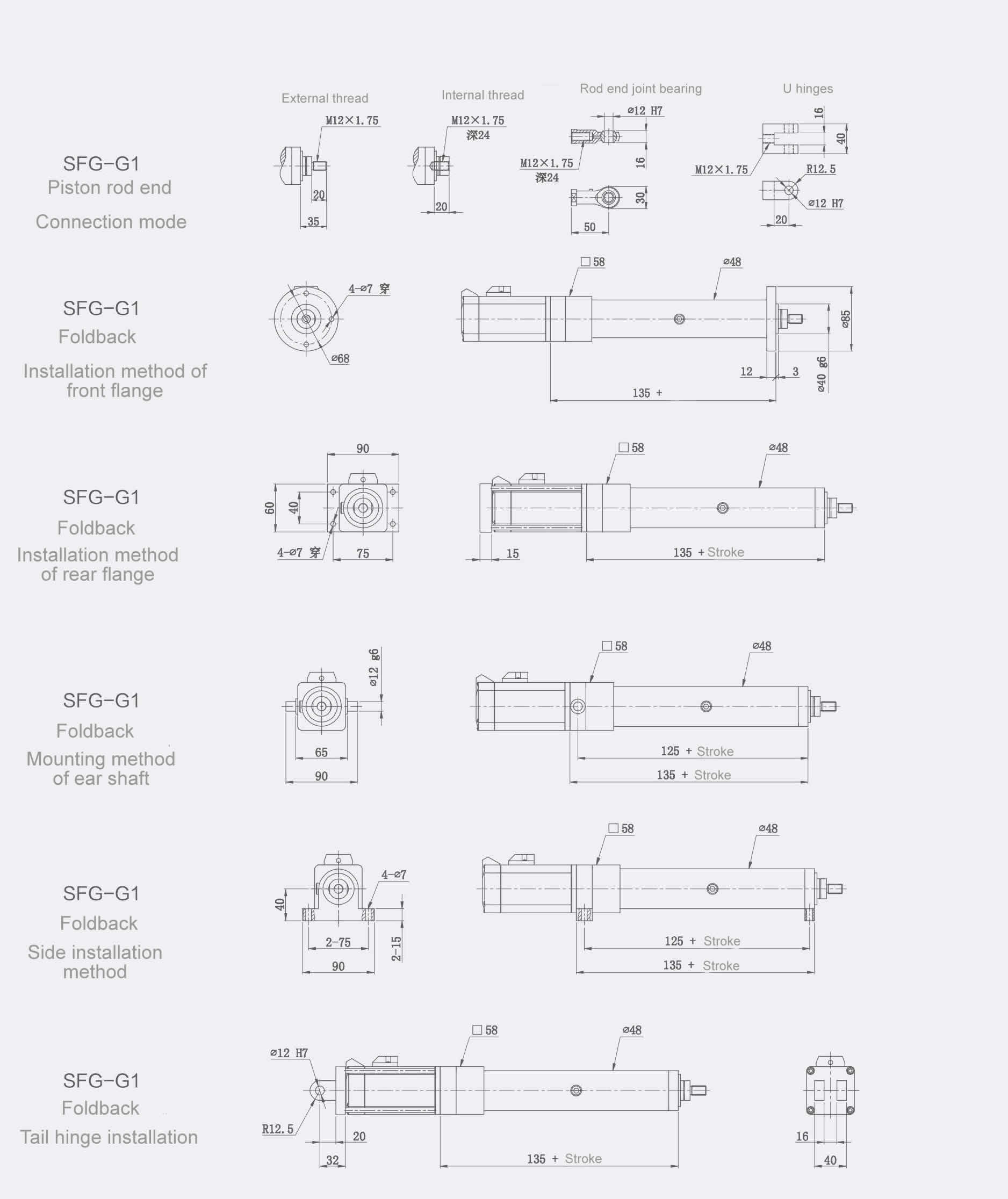

SFG series electric cylinder adopts advanced modular design method, which has compact structure, small shape, high performance, high precision, high reliability, and long service life.

Main Features

Shell: hard aluminum alloy, with smooth and beautiful treatment. It used No. 45 steel to realize strong bearing capacity.

Piston rod (Telescopic push rod): hard chrome plating on the surface, wear resistance, corrosion resistance; SUS304, suitable for special needs.

Precision: Repeated positioning precision up to ±0.05mm; If it adopts grinding grade ball screw, the repeated positioning precision can be as high as ± 0.02mm; Besides, if it equiped with closed loop control (add light ruler, encoder), repeated positioning precision can reach ± 0.01mm. It can meet the requirements for different applications.

Thrust: Additional deceleration and other mechanisms can be added to reduce the power of the motor and achieve high thrust. Protection class: IP65, IP67.

Itinerary: can be customized according to the customer’s needs.

Motor selection: AC servo motor, high precision, fast speed, small size, quick response, good acceleration performance, and high thrust.

Stepper motor: high accuracy, slow speed, and little thrust.

Common DC motor: suitable for low voltage power supply, can not be positioned, thrust is not large, and wide speed regulating scope.

Three-phase asynchronous motor: It is suitable for applications where only motion requirements are required and displacement accuracy is not required.

Ansökan

Aerospace test, multiple degrees of freedom simulation, multi-DOF dynamic entertainment, multi-DOF precision machining, robotics, mechanical lifting platform, automotive press, automobile manufacturing equipment, machinery and automated production lines, steel casting, petrochemical, material handling , injection molding machine, mold control, valve control, precision machine tools, pharmaceutical machinery, food industry and other fields.

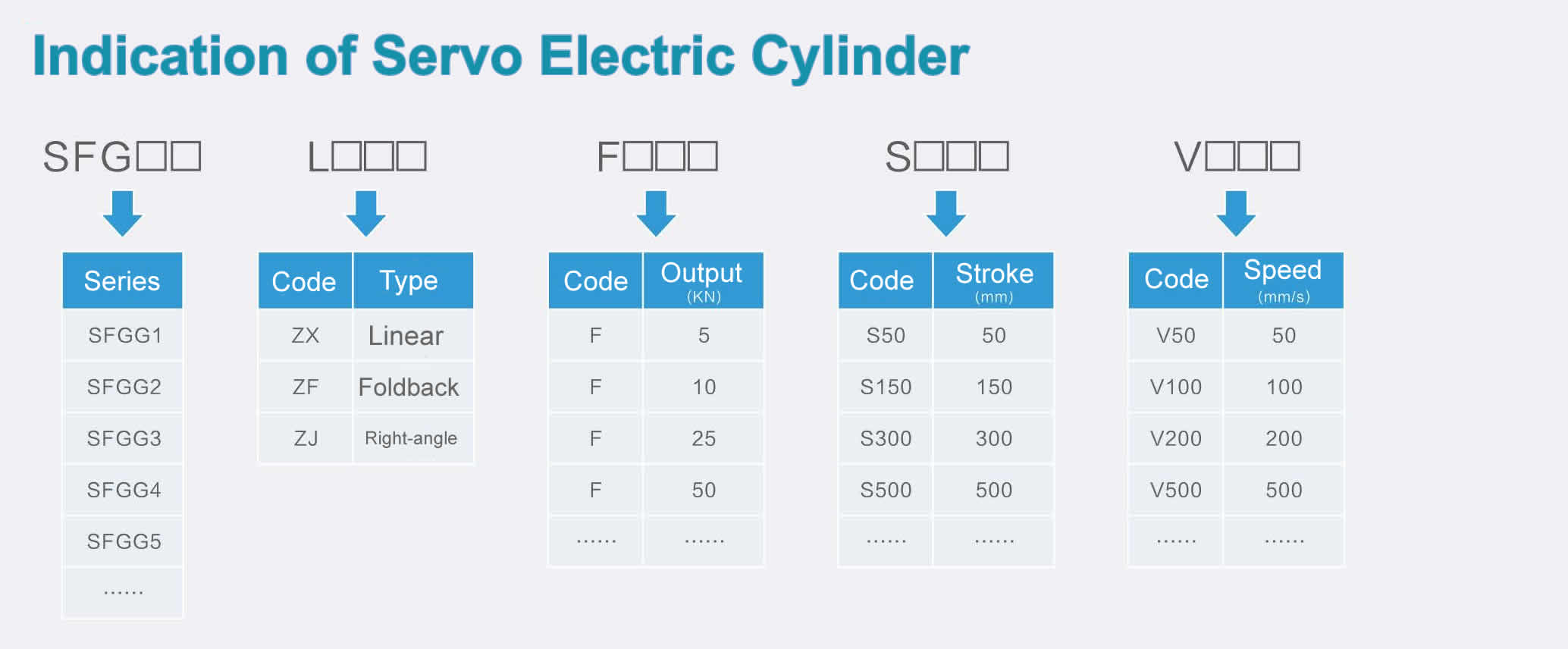

Indication of Model Numbers of Servo Electric Cylinder

Overview of Servo Electric Cylinder

Overview of Servo Electric Cylinder