Overview of AT-FL1/R1 Speed Reducer

Overview of AT-FL1/R1 Speed Reducer

- Single shaft output configuration.

- Right (AT-FL1) or left (AT-FL1) output shaft for selection.

- 3 Stages with reduction ratio from 1~500.

- Nine models for 1-stage and 2-stage steering gearbox, six models for 3-stage reducer.

- Flange input type of servo gearbox.

- 6~10 arcmin backlash with different reduction ratios.

- High torque up to 8000 Nm and high efficiency of 98%.

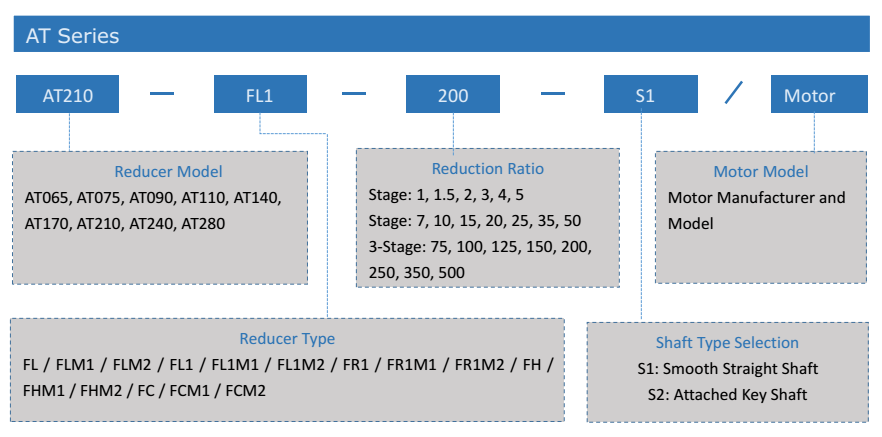

Indication of Model Numbers of ATF Steering Gearbox

Description of AT-FL1/FR1 High Precision Серво Коробка передач

The TQG AT-FL1/AT-FR1 series planetary gearbox is a servo speed reducer with single output shaft and flanged input configuration on the motor side. AT-FL1/AT-FR1 is a right angle gearbox with spiral bevel gears which contributes to high precision and a high radial load capacity. They are widely matched for all brands of servo motors and stepper motor on the market.

Three stages of right angle gearboxes are available:

1-stage ( reduction ratio i=1~5 )

Models: AT065 FL1/FR1, AT075 FL1/FR1, AT090 FL1/FR1, AT110 FL1/FR1, AT140 FL1/FR1, AT170 FL1/FR1, AT210 FL1/FR1, AT240 FL1/FR1, AT280 FL1/FR1.

2-stage ( reduction ratio i=7~50 )

Models: AT065 FL1/FR1, AT075 FL1/FR1, AT090 FL1/FR1, AT110 FL1/FR1, AT140 FL1/FR1, AT170 FL1/FR1, AT210 FL1/FR1, AT240 FL1/FR1, AT280 FL1/FR1.

3-Stage ( reduction ratio i=75~500)

Models: AT110 FL1/FR1, AT140 FL1/FR1, AT170 FL1/FR1, AT210 FL1/FR1, AT240 FL1/FR1, AT280 FL1/FR1.

Q. Why the output force of precision planetary reducer is too small?

If the output force of precision planetary gearbox is too small, the shaft is easily broken. And what are the reasons that easily leads to this condition?

First of all, the wrong model selection results in the insufficient output torque of the precision planetary gear reducer that is equipped. When select the model, some users wrongly believed that as long as the nominated torque of the selected precision planetary reducer can meet the working requirement, that will be ok. Actually, it it not true. Firstly, the rated output torque of the matched motor is multiplied by reduction ratio equals to a data which is in principle should be smaller than the nominated output torque of the similar planetary reducer on the catalogue. Secondly, the overload capacity of the drive motor and the actual required maximum working torque should also be considered at the same time. In theory, the maximum operating torque the user needs must be less than 2 times of the rated output torque of the planetary reducer.

Overview of AT-FL1/R1 Speed Reducer

Overview of AT-FL1/R1 Speed Reducer